Condenser Loop - Cooling Tower[LINK]

The Condenser Loop is constructed by using a PlantLoop object. It uses a cooling tower (modeled by using a CoolingTower:SingleSpeed object class) and a variable speed pump (modeled by using a Pump:VariableSpeed) to supply cooling water to the chillers in the primary cooling loop. Therefore, the supply side of the loop contains the Cooling Tower and the demand side contains the chillers. The loop is operated by using plant equipment operation schemes, and schedules. Refer to Figure 116 for a simple diagram of the Condenser Loop.

Figure 116 - Simple line diagram for the condenser loop

This series of flowcharts serve as a guide for identifying and inputting the Condenser Loop and its components into the input file. The EnergyPlus line diagram for this loop is provided in Figure 117. A simple flowchart for the separation of the half loops is provided in Figure 118.

Figure 117 - EnergyPlus line diagram for the condenser loop

Figure 118 - Simple flow chart for separation on half loops in the condenser loop

Condenser Loop Supply Side Construction[LINK]

The main components on the supply side half loop for the Condenser Loop are the Cooling Tower that supplies the cooling water and the variable speed pump that circulates the cooling water through the loop. This half loop supplies cooling water to the chillers on the demand side half loop. The supply side half loop contains four components, four branches, eight nodes, and one splitter-mixer pair. The EnergyPlus line diagram for the Condenser loop supply side is provided in Figure 119. The flowchart for supply side branches and components is provided in Figure 120. The flowchart for supply side connectors is provided in Figure 121.

Figure 119 - EnergyPlus line diagram for the supply side of the Condenser Loop

Figure 120 – Flowchart for Condenser Loop supply side branches and components

Figure 121 – Flowchart for Condenser Loop supply side connectors

Condenser Loop Demand Side Construction[LINK]

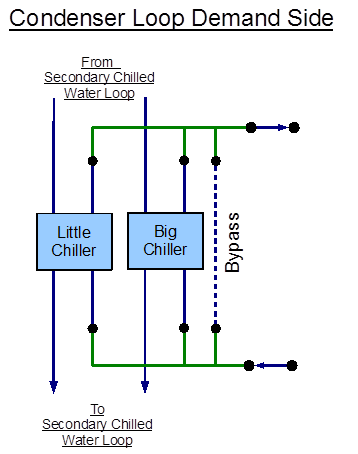

The main components on the demand side half loop are the small constant COP chiller and the bigger electric chiller that use the cooling water supplied by the cooling tower. The chillers are in turn used to supply chilled water in the Primary Cooling loop. This side of the loop also has ten nodes, five components, five branches and one splitter-mixer pair. An EnergyPlus schematic for the demand side is provided in Figure 122. The flowchart for demand side branch definition is provided in Figure 123. The flowchart for the demand side connectors is provided in Figure 123.

Figure 122 - EnergyPlus line diagram for the demand side of the Condenser Loop

Figure 123 – Flowchart for Condenser Loop demand side branches and components

Figure 124 – Flowchart for Condenser Loop demand side connectors

Flowcharts for Condenser Loop Controls[LINK]

The Condenser loop is operated by using set-points, plant equipment operation schemes and schedules.

Condenser Loop Schedules[LINK]

The flowchart for condenser loop schedule definition is provided in Figure 125. The Condenser loop uses one schedule to operate properly. ON is a compact schedule that keeps the Cooling Tower On at all times of the day, this compact schedule uses a continuous ScheduleTypeLimit (Fraction) which defines that the value of On is 1 and that of Off is 0.

Figure 125 – Flowchart for condenser loop schedules

Condenser Loop Plant Equipment Operation Schemes[LINK]

The PlantEquipmentOperationschemes object uses the ON schedule and the Tower Operation objects to set the range of demand loads for which the cooling tower is operated during the simulation period. A flowchart detailing the Condenser Loop plant equipment operation schemes is provided in Figure 126.

Figure 126 – Flowchart for Condenser Loop plant equipment operation schemes

Condenser Loop Setpoints[LINK]

The MyCondenserControl setpoint manager places a temperature setpoint at the Condenser Supply Outlet Node. The temperature at this point is controlled with respect to the outdoor air wet bulb temperature at that point in the simulation. The outdoor air wet bulb temperature is obtained from the weather data at the location of the simulation. A flowchart for Secondary Cooling loop setpoints is provided in Figure 127.

Figure 127 – Flowchart for Condenser Loop setpoints

Condenser Loop - Cooling Tower[LINK]

The Condenser Loop is constructed by using a PlantLoop object. It uses a cooling tower (modeled by using a CoolingTower:SingleSpeed object class) and a variable speed pump (modeled by using a Pump:VariableSpeed) to supply cooling water to the chillers in the primary cooling loop. Therefore, the supply side of the loop contains the Cooling Tower and the demand side contains the chillers. The loop is operated by using plant equipment operation schemes, and schedules. Refer to Figure 116 for a simple diagram of the Condenser Loop.

Figure 116 - Simple line diagram for the condenser loop

Flowcharts for the Condenser Loop Input Process[LINK]

This series of flowcharts serve as a guide for identifying and inputting the Condenser Loop and its components into the input file. The EnergyPlus line diagram for this loop is provided in Figure 117. A simple flowchart for the separation of the half loops is provided in Figure 118.

Figure 117 - EnergyPlus line diagram for the condenser loop

Figure 118 - Simple flow chart for separation on half loops in the condenser loop

Condenser Loop Supply Side Construction[LINK]

The main components on the supply side half loop for the Condenser Loop are the Cooling Tower that supplies the cooling water and the variable speed pump that circulates the cooling water through the loop. This half loop supplies cooling water to the chillers on the demand side half loop. The supply side half loop contains four components, four branches, eight nodes, and one splitter-mixer pair. The EnergyPlus line diagram for the Condenser loop supply side is provided in Figure 119. The flowchart for supply side branches and components is provided in Figure 120. The flowchart for supply side connectors is provided in Figure 121.

Figure 119 - EnergyPlus line diagram for the supply side of the Condenser Loop

Figure 120 – Flowchart for Condenser Loop supply side branches and components

Figure 121 – Flowchart for Condenser Loop supply side connectors

Condenser Loop Demand Side Construction[LINK]

The main components on the demand side half loop are the small constant COP chiller and the bigger electric chiller that use the cooling water supplied by the cooling tower. The chillers are in turn used to supply chilled water in the Primary Cooling loop. This side of the loop also has ten nodes, five components, five branches and one splitter-mixer pair. An EnergyPlus schematic for the demand side is provided in Figure 122. The flowchart for demand side branch definition is provided in Figure 123. The flowchart for the demand side connectors is provided in Figure 123.

Figure 122 - EnergyPlus line diagram for the demand side of the Condenser Loop

Figure 123 – Flowchart for Condenser Loop demand side branches and components

Figure 124 – Flowchart for Condenser Loop demand side connectors

Flowcharts for Condenser Loop Controls[LINK]

The Condenser loop is operated by using set-points, plant equipment operation schemes and schedules.

Condenser Loop Schedules[LINK]

The flowchart for condenser loop schedule definition is provided in Figure 125. The Condenser loop uses one schedule to operate properly. ON is a compact schedule that keeps the Cooling Tower On at all times of the day, this compact schedule uses a continuous ScheduleTypeLimit (Fraction) which defines that the value of On is 1 and that of Off is 0.

Figure 125 – Flowchart for condenser loop schedules

Condenser Loop Plant Equipment Operation Schemes[LINK]

The PlantEquipmentOperationschemes object uses the ON schedule and the Tower Operation objects to set the range of demand loads for which the cooling tower is operated during the simulation period. A flowchart detailing the Condenser Loop plant equipment operation schemes is provided in Figure 126.

Figure 126 – Flowchart for Condenser Loop plant equipment operation schemes

Condenser Loop Setpoints[LINK]

The MyCondenserControl setpoint manager places a temperature setpoint at the Condenser Supply Outlet Node. The temperature at this point is controlled with respect to the outdoor air wet bulb temperature at that point in the simulation. The outdoor air wet bulb temperature is obtained from the weather data at the location of the simulation. A flowchart for Secondary Cooling loop setpoints is provided in Figure 127.

Figure 127 – Flowchart for Condenser Loop setpoints

Documentation content copyright © 1996-2015 The Board of Trustees of the University of Illinois and the Regents of the University of California through the Ernest Orlando Lawrence Berkeley National Laboratory. All rights reserved. EnergyPlus is a trademark of the US Department of Energy.

This documentation is made available under the EnergyPlus Open Source License v1.0.