Performance tables provide a method to enter specific performance data in tabular form. Tabular data represent equipment performance in a manner similar to performance curves, however, the necessity to formulate the equation coefficient is not required. Tabular data may be used to directly interpolate the actual data within the tables independent variable limits or a regression analysis may be performed to calculate the equation coefficients and use these coefficients for the associated engineering calculations. When direct interpolation is selected, the tabular data is interpolated linearly between the first independent variable and then, if used, the second independent variable. The name of a table object may be used interchangeably in any valid field where a performance curve name is required.

Tables based on a single independent variable[LINK]

The tabular data entered for polynomials with a single independent variable represent x and outupt data pairs as described in the previous section for performance curves. The x in each of the previous equations represent the independent variable (model input) and the output represents the dependent variable. The data pairs are organized as the data point for the independent variable followed by the data point for the dependent variable. The data pairs form a one-dimensional array that may either be linearly interpolated, interpolated based on a polynomial equation, or this data may be used to calculate the equation coefficients (a-e) as described in the previous section.

The equation form is user selected as either linear, quadratic, cubic, quartic, or exponent. This choice determines: 1) where this table object may be used (i.e., certain objects may required a specific form of the equation), and 2) the degree or order used to calculate the regression coefficients. The following example describes the methodology used when tabular input data is used in place of common performance curve objects. Although Energyplus does not use a performance curve in the manner described in this example, this example is ideally suited for teaching the basics of tabular data entry.

Given a generic manufacturer’s fan data for a fan having a maximum flow rate of 5 m3/s and power of 125 W, the power is shown in Table [table:generic-manufacturers-fan-data] below to be proportional to the cube of flow rate. Since, in this example, the flow rate is not a valid input for calculating fan power, the flow rate will be converted to flow fraction (or PLR). The power data is entered as the actual fan power and will be normalized by the program according to the maximum power of 125 W. Also shown here are the performance curve outputs using the regression coefficients calculated by the program. The performance curve outputs represent the fan power ratio as a function of flow fraction. Additional significant digits are included to show the impact a given data set may have on the resulting coefficients (i.e., not quite 0 at the zero crossing, rounding causes slight errors in the actual coefficient values, etc).

Generic Manufacturer’s Fan Data

| 0 |

0 |

0 |

-1.1102230246E-16 |

| 0.5 |

0.1 |

0.125 |

0.00100000000000018 |

| 1 |

0.2 |

1 |

0.00800000000000004 |

| 3 |

0.6 |

27 |

0.215999999999995 |

| 4 |

0.8 |

64 |

0.51199999999999 |

The tabular data can be entered directly into a table object. The data for flow fraction (or fan part-load ratio) and power are entered as data pairs. As this example describes how the fan power changes with changes in air flow, the curve type selected is Cubic and, therefore, the minimum number of data pairs equals 4 (i.e., number of coefficients in a cubic equation) although 5 are used in this example. In addition, since calculating regression coefficients for this data set would yield more accurate results than linearly interpolating this data set, the selection is made to evaluate the curve to the limits specified. In this example, the fan in question is capable of operating up to 5 m3/s at 125 Watts (which is purposely not provided in this set of tabular data). We need this information because we want to create a fan power ratio equation with an input of 0-1 for fan part-load ratio and a table output of 0-1 for fan power ratio. Therefore, the tabular data need to be normalized at a part-load ratio of 1 (i.e., normalized to the power at full flow). The following Table object describes the input necessary for this particular data set.

Table:OneIndependentVariable,

MyFanPower, !- Name [Fit from catalog performance data]

Cubic, !- Curve Type

EvaluateCurveToLimits, !- Interpolation Type

0, !- Minimum Value of X1,

1, !- Maximum Value of X1,

0, !- Minimum Table Output

64, !- Maximum Table Output

Dimensionless, !- Input Unit Type for X1

Dimensionless, !- Output Unit Type

125, !- Normalization Point

0.8,64, !- X Value #1, Output Value #1

0,0.0, !- X Value #2, Output Value #2

0.2,1, !- X Value #3, Output Value #3

0.1,0.125, !- X Value #4, Output Value #4

0.6,27; !- X Value #5, Output Value #5

Notice in this example that:

The data pairs do not need to be entered in ascending order, this data set will automatically be re-ordered in ascending order by the program.

The minimum and maximum table output entered by the user uses the same units as the output values and are subsequently normalized in the same manner as the dependent variable in the data pairs.

For the resulting curve object (see below), the minimum (maximum) limits are based on the lesser (greater) of the user entered value and the lower (upper) limit of the tabular data. When linearly interpolating tabular data, the limits of the data set are used unless the user entered maximum is more restrictive (e.g., 64 W in this example is not more restrictive than the data set).

For the resulting curve object, the calculated coefficients may not perfectly represent the data set (i.e., in this example coefficient 1, 2, and 3 should have been 0). Duplicating the 0,0 data pair four additional times (to weight the 0 crossing) yields constant coefficients of 0. This could also be changed manually in the curve object created by the program.

Referring to Figure [fig:fan-power-ratio-example], a selection of LinearInterpolationOfTable would interpolate the tabular data within the limits of the data set (blue circles) resulting in a maximum X and Curve value of 0.8 and 0.512 (i.e., 64/125), respectively. Selecting EvaluateCurveToLimits allows extrapolation of the data set up to a power ratio of 1 had 125 W been entered as the maximum table output in this example.

In the graph below, the linearly interpolated tabular data (blue line) represent a less accurate fan power ratio curve than the performance curve itself (red line). In this specific example, it is more accurate to rely on the performance curve results (i.e., Interpolation Type = EvaluateCurveToLimits in table object). In addition, the performance curve is able to extrapolate outside the limits of the data set since the regression analysis provides a smooth continuous curve through 1. Selecting the LagrangeInterpolationLinearExtrapolation interpolation method with a cubic curve type is similar to the performance curve results.

Including additional data in the table object (e.g., data points for flow fractions = 0.4 and 1) would allow direct linear interpolation of the tabular data without significant loss of accuracy compared to the performance curve or lagrange methods.

Curve output in eio file (when using Output:Diagnostics, DisplayAdvancedReportVariables):

!...GENERATING NEW CURVE OBJECT

! Input as Table:OneIndependentVariable "MYFANPOWER"

! RSquared = 1.0000000000

! Standard Error = 7.3549798168E-016

! Degrees of Freedom = 5

Curve:Cubic,

MYFANPOWER, !- Name

-1.1102230246E-016, !- Coefficient1 Constant

5.0571599639E-015, !- Coefficient2 x

-2.1582431250E-014, !- Coefficient3 x**2

1.0000000000, !- Coefficient3 x**3

0.0000000000, !- Minimum Value of x

1.0000000000, !- Maximum Value of x

0.0000000000, !- Minimum Curve Output

1.0000000000; !- Maximum Curve Output

!...END GENERATING NEW CURVE OBJECT

![Fan Power Ratio Example [fig:fan-power-ratio-example]](media/image7870.png)

Tables based on two independent variables[LINK]

The tabular data entered for polynomials with two independent variables represent x, y and output data pairs as described in the previous section for performance curves. The x and y in each of the previous equations represent the independent variables (model inputs) and the output represents the dependent variable. The data pairs are organized as the data points for the independent variables followed by the data point for the dependent variable. The order of the data is significant in that the x and y data are entered in the same order as shown in the model’s fundamental equation. The data pairs form a two-dimensional array that may either be linearly interpolated, interpolated using a second order polynomial, or this data may be used to calculate the equation coefficients (a-f) as described in the previous section.

The equation order or degree is user selected as biquadratic or quadraticlinear. This choice determines: 1) where this table object may be used (i.e., certain objects may required a specific form of the equation), and 2) the fundamental equation used to calculate the regression coefficients. The following example describes the methodology used when tabular input data is used in place of common performance curve objects.

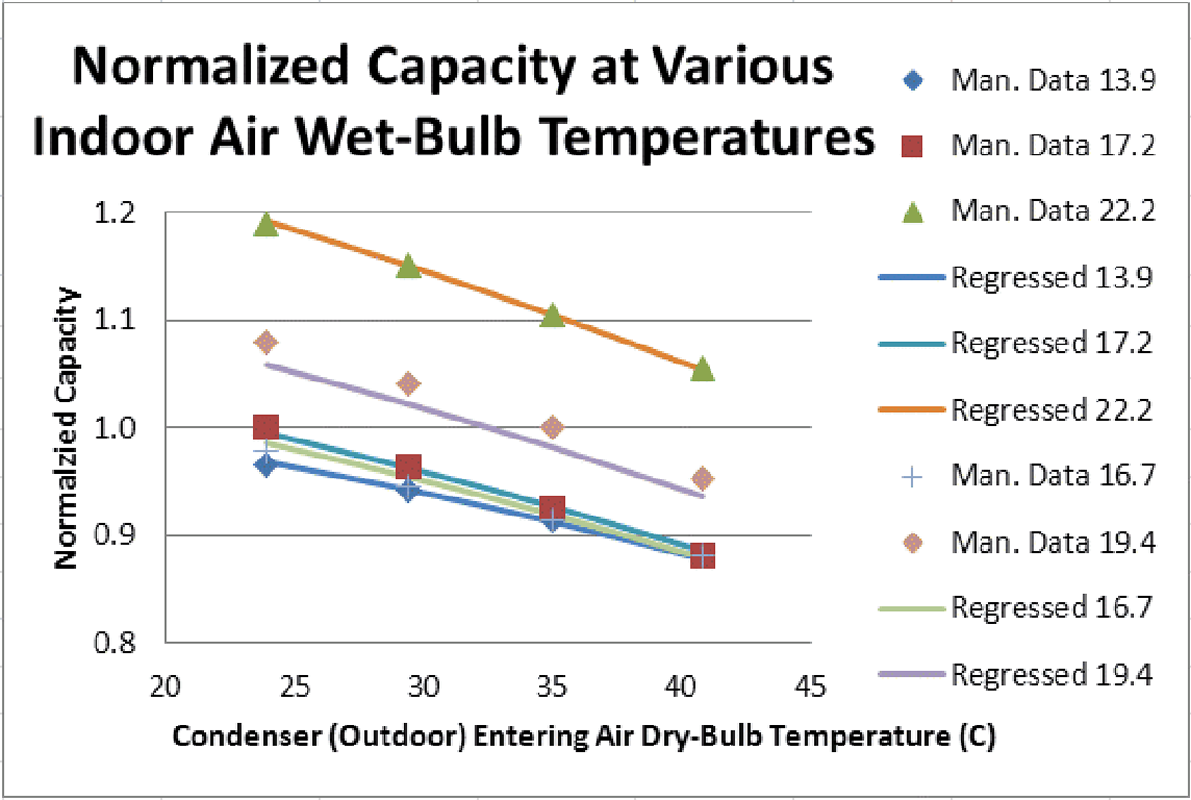

Given a generic manufacturer’s air conditioner data for an AC system having a rated total cooling capacity of 7735.1 W, the change in capacity is shown in the table to be a function of both cooling coil entering air wet-bulb temperature and condenser entering air dry-bulb temperature. The tabular data is entered as the actual cooling capacity and will be normalized by the program according to the rated capacity of 7735.1 W. The cooling coil EIR curve could be developed in a similar fashion, except that EIR (Power/TotCap) must first be calculated from the tabular data below BEFORE entering this data into a table object. In this example shown in Figure [fig:generic-manufacturers-normalized-capacity-example], only data highlighted in yellow will be used.

![Generic Manufacturer’s Normalized Capacity Example [fig:generic-manufacturers-normalized-capacity-example]](media/image7871.png)

The tabular data can be entered directly into a table object. As an example, for an air-cooled DX cooling coil object in EnergyPlus, the capacity as a function of temperature has the following fundamental equation (Ref. Single-Speed Electric DX Air Cooling Coil):

TotCapTempModFac=a+b(Twb,i)+c(Twb,i)2+d(Tc,i)+e(Tc,i)2+f(Twb,i)(Tc,i)

where:

Twb,i is the wet-bulb temperature of the air entering the cooling coil (∘C)

Tc,i is the dry-bulb temperature of the air entering an air-cooled condenser (∘C).

Given this form of the fundamental equation, the data pairs for the cooling coil are entered as entering air wet-bulb temperature, condenser entering dry-bulb temperature, and total cooling capacity. These 3 values, in this precise order, make up each data pair. As this example describes how the DX coil cooling capacity changes with changes in indoor and outdoor temperature, the curve type selected is BiQuadratic and, therefore, the minimum number of data pairs equals 6 (i.e., number of coefficients in the equation above). Evaluating this tabular data based on regression coefficients may be less desirable to the user since the data in the lower right corner of the table is somewhat flat due to controls or other hardware constraints. For the sake of this example, the regression analysis is chosen. In this example, the DX cooling coil total cooling capacity at the ARI rating point is used to normalize the capacity data (e.g., 7735.1 W at 19.4∘C EWB and 35∘C outdoor dry-bulb temperature). In addition, the minimum and maximum limits are chosen such that extrapolation of the performance curve is allowed. Notice in the example below that:

The data pairs do not need to be entered in ascending order, this data set will automatically be re-ordered in ascending order by the program.

As shown in the table object below, only three of the five entries for entering air wet-bulb temperature were entered in the table object and therefore used for the regression analysis. This data entry technique may save time when entering a large data set, however, it may have unforeseen consequences on the resulting regression coefficients (i.e., the coefficients may provide less accuracy than desired). Note in the figure below the difference between the manufacturers data at 19.4∘C entering air wet-bulb temperature vs the prediction made by the regression coefficients. Since this data set (i.e., the 4 data points at 19.4∘C entering air wet-bulb temperature from the table above) was left out of the regression analysis, the predicted capacity at this condition is slightly under-estimated.

The minimum and maximum table output entered by the user uses the same units as the output values and are subsequently normalized in the same manner as the dependent variable in the data pairs.

For the resulting curve object, the minimum (maximum) limits are based on the lesser (greater) of the user entered value and the lower (upper) limit of the tabular data. When linearly interpolating tabular data, only the limits of the data set are used.

For the resulting curve object, the calculated coefficients may not perfectly represent the entire data set since all data was not used (i.e., in this example the regressed data do not line up exactly with all the manufacturers data, however, do line up well with the data included in the table object).

Selecting LinearInterpolationOfTable would interpolate the tabular data within the limits of the data set (characters) resulting in a maximum X1, X2 and Curve value of 22.2, 40.8 and 1.25 (i.e., 9206.0/7375.1), respectively. Note how these maximum values compare to the maximum values in the generated curve object below which chose the EvaluateCurveToLimits option instead (i.e., the user min/max inputs were used to generate these fields when creating the curve object). The minimum values would be affected in a similar manner. Selecting Lagrange or EvaluateCurveToLimits allows extrapolation of the data set to values specified by the user.

In the graph below, the linearly interpolated tabular data (character data set representing manufacturers data) may better represent the capacity ratio than the performance curve (lines representing the regressed data) given the non-linear relationship between capacity and temperature shown in the table and/or graph. However, extrapolation of the data set is performed linearly and the second order affects of temperature would be lost when extrapolating. Either the data set would be expanded to include other relevant data (e.g., data at colder outdoor temperatures where cooling may be required) which could then be interpolated or additional existing data could be added to the table object to allow more accurate regression coefficients to be used to predict data outside the table data limits.

Table:TwoIndependentVariables,

CCoolCapFT, !- Name [Fit from catalog performance data]

BiQuadratic, !- Curve Type

EvaluateCurveToLimits, !- Interpolation Type

1, !- Minimum Value of x,

30, !- Maximum Value of x,

5, !- Minimum Value of y,

50, !- Maximum Value of y,

4500, !- Minimum Table Output

15000, !- Maximum Table Output

Temperature, !- Input Unit Type for x

Temperature, !- Input Unit Type for y

Dimensionless, !- Output Unit Type

7735.1, !- Normalization Point

17.2,29.4,7462.6, !- X, Y, and Output data pair #1

17.2,23.9,7735.1, !- X, Y, and Output data pair #2

13.9,29.4,7283.9, !- X, Y, and Output data pair #3

13.9,23.9,7474.4, !- X, Y, and Output data pair #4

13.9,35,7067.1, !- X, Y, and Output data pair #5

13.9,40.8,6818.0, !- X, Y, and Output data pair #6

17.2,35,7157.9, !- X, Y, and Output data pair #7

17.2,40.8,6818.0, !- X, Y, and Output data pair #8

22.2,35,8552.6, !- X, Y, and Output data pair #9

22.2,29.4,8898.3, !- X, Y, and Output data pair #10

22.2,23.9,9206.0, !- X, Y, and Output data pair #11

22.2,40.8,8165.8; !- X, Y, and Output data pair #12

Curve output in eio file (when using Output:Diagnostics, DisplayAdvancedReportVariables):

CREATING NEW CURVE OBJECT

! Input as Table:TwoIndependentVariables "CCOOLCAPFT"

! RSquared = 0.9993993101

! Standard Error = 3.4649248573E-003

! Sample Size = 12

Curve:BiQuadratic,

FromTable_CCOOLCAPFT, !- Name

1.7214120578, !- Coefficient1 Constant

-0.1011737262, !- Coefficient2 x

3.7738833967E-003, !- Coefficient3 x**2

2.8686934910E-003, !- Coefficient4 y

-5.3785351258E-005, !- Coefficient5 y**2

-3.4086036156E-004, !- Coefficient6 x*y

1.0000000000, !- Minimum Value of x

30.0000000000, !- Maximum Value of x

5.0000000000, !- Minimum Value of y

50.0000000000, !- Maximum Value of y

0.5817636488, !- Minimum Curve Output

1.9392121627; !- Maximum Curve Output

END CREATING NEW CURVE OBJECT

Lookup Tables[LINK]

Lookup tables provide a method to evaluate a group of data that may or may not conform to a fundamental equation. Only tabular data which conform to existing performance curve equations are currently allowed (i.e., that lookup table name is entered where any valid performance curve is allowed therefore the table data must conform to the models fundamental equation for that specific curve). Efforts to include this lookup table in the energy management system would allow custom use of lookup tables, however, calling lookup tables from the EMS system is not currenly possible. Lookup tables can interpolate the actual data using a non-linear polynomial equation (order higher than 1). As with other table or curve objects, the lookup table can be used anywhere a valid curve object name is allowed. Care must be taken to ensure the table data format is consistent with the associate model that is using the performance curve (e.g., DX cooling coil capacity as a function of temperature where independent variable X1 = indoor wet-bulb temperature and independent variable X2 = outdoor dry-bulb temperature).

The lookup tables are evaluated using the Lagrange form of the interpolation polynomial or the previously described interpolation methods of LinearInterpolationOfTable and EvaluateCurveToLimits. When using the Lagrange method, the number of points used in the interpolation is equal to 1 plus the polynomial order (e.g., a second order interpolation would use 3 points).

pn(x)=n∑i=0yili(x)

li(x)=Πj≠i(x−xjxi−xj)i=0,1,...,n

First-order Lagrange interpolation polynomial:

p1(x)=(x−x1)(x0−x1)y0+(x−x0)(x1−x0)y1

Second-order Lagrange interpolation polynomial:

p2(x)=(x−x1)(x−x2)(x0−x1)(x0−x2)y0+(x−x0)(x−x2)(x1−x0)(x1−x2)y1+(x−x0)(x−x1)(x2−x0)(x2−x1)y2

Third-order Lagrange interpolation polynomial:

p3(x)=(x−x1)(x−x2)(x−x3)(x0−x1)(x0−x2)(x0−x3)y0+(x−x0)(x−x2)(x−x3)(x1−x0)(x1−x2)(x1−x3)y1+(x−x0)(x−x1)(x−x3)(x2−x0)(x2−x1)(x2−x3)y2+(x−x0)(x−x1)(x−x2)(x3−x0)(x3−x1)(x3−x2)y3

where:

x is the interpolation point

xn is the x value of tabular data

yn is the y value of tabular data

pi(n) is the polynomial (table) output.

The lookup table is interpolated using the interpolation polynomial shown above. If the table input value (interpolation point) is near the bottom edge or exceeds the table boundaries, a linear extrapolation is used (2-point extrapolation). The interpolation order is determined by the user entered number of interpolation points.

A regression analysis may be performed on any lookup table having one or two indpenedent variables. As with performance tables, the resulting performance curve coefficients are calculated and used in the simulation only when the interpolation method is selected as EvaluateCurveToLimits. In addition, the performance curve is only written to the eio file when the output diagnostics flag is set to DisplayAdvancedReportVariables (ref. Output:Diagnostics, DisplayAdvancedReportVariables).

Using the example provided in the section above for Tables based on two indpendent variables, the lookup table object would be defined as follows:

Table:MultiVariableLookup,

CCoolCapFT,

EvaluateCurveToLimits,

3,

BiQuadratic,

SingleLineIndependentVariableWithMatrix,

,

ASCENDING,

ASCENDING,

7735.1, !- Normalization reference

1, !- Minimum Value of X1

30, !- Maximum Value of X1

5, !- Minimum Value of X2

50, !- Maximum Value of X2

, !- Minimum Value of X3

, !- Maximum Value of X3

, !- Minimum Value of X4

, !- Maximum Value of X4

, !- Minimum Value of X5

, !- Maximum Value of X5

4500, !- Minimum Table Output

15000, !- Maximum Table Output

Temperature, !- Input Unit Type for X1

Temperature, !- Input Unit Type for X2

, !- Input Unit Type for X3

, !- Input Unit Type for X4

, !- Input Unit Type for X5

Dimensionless, !- Output Unit Type

2, 3, 4,

13.9, 17.2, 22.2,

23.9, 29.4, 35.0, 40.8,

7474.4, 7735.1, 9206.0,

7283.9, 7462.6, 8898.3,

7067.1, 7157.9, 8552.6,

6818.0, 6818.0, 8165.8;

Performance Tables[LINK]

Performance tables provide a method to enter specific performance data in tabular form. Tabular data represent equipment performance in a manner similar to performance curves, however, the necessity to formulate the equation coefficient is not required. Tabular data may be used to directly interpolate the actual data within the tables independent variable limits or a regression analysis may be performed to calculate the equation coefficients and use these coefficients for the associated engineering calculations. When direct interpolation is selected, the tabular data is interpolated linearly between the first independent variable and then, if used, the second independent variable. The name of a table object may be used interchangeably in any valid field where a performance curve name is required.

Tables based on a single independent variable[LINK]

The tabular data entered for polynomials with a single independent variable represent x and outupt data pairs as described in the previous section for performance curves. The x in each of the previous equations represent the independent variable (model input) and the output represents the dependent variable. The data pairs are organized as the data point for the independent variable followed by the data point for the dependent variable. The data pairs form a one-dimensional array that may either be linearly interpolated, interpolated based on a polynomial equation, or this data may be used to calculate the equation coefficients (a-e) as described in the previous section.

The equation form is user selected as either linear, quadratic, cubic, quartic, or exponent. This choice determines: 1) where this table object may be used (i.e., certain objects may required a specific form of the equation), and 2) the degree or order used to calculate the regression coefficients. The following example describes the methodology used when tabular input data is used in place of common performance curve objects. Although Energyplus does not use a performance curve in the manner described in this example, this example is ideally suited for teaching the basics of tabular data entry.

Given a generic manufacturer’s fan data for a fan having a maximum flow rate of 5 m3/s and power of 125 W, the power is shown in Table [table:generic-manufacturers-fan-data] below to be proportional to the cube of flow rate. Since, in this example, the flow rate is not a valid input for calculating fan power, the flow rate will be converted to flow fraction (or PLR). The power data is entered as the actual fan power and will be normalized by the program according to the maximum power of 125 W. Also shown here are the performance curve outputs using the regression coefficients calculated by the program. The performance curve outputs represent the fan power ratio as a function of flow fraction. Additional significant digits are included to show the impact a given data set may have on the resulting coefficients (i.e., not quite 0 at the zero crossing, rounding causes slight errors in the actual coefficient values, etc).

The tabular data can be entered directly into a table object. The data for flow fraction (or fan part-load ratio) and power are entered as data pairs. As this example describes how the fan power changes with changes in air flow, the curve type selected is Cubic and, therefore, the minimum number of data pairs equals 4 (i.e., number of coefficients in a cubic equation) although 5 are used in this example. In addition, since calculating regression coefficients for this data set would yield more accurate results than linearly interpolating this data set, the selection is made to evaluate the curve to the limits specified. In this example, the fan in question is capable of operating up to 5 m3/s at 125 Watts (which is purposely not provided in this set of tabular data). We need this information because we want to create a fan power ratio equation with an input of 0-1 for fan part-load ratio and a table output of 0-1 for fan power ratio. Therefore, the tabular data need to be normalized at a part-load ratio of 1 (i.e., normalized to the power at full flow). The following Table object describes the input necessary for this particular data set.

Notice in this example that:

The data pairs do not need to be entered in ascending order, this data set will automatically be re-ordered in ascending order by the program.

The minimum and maximum table output entered by the user uses the same units as the output values and are subsequently normalized in the same manner as the dependent variable in the data pairs.

For the resulting curve object (see below), the minimum (maximum) limits are based on the lesser (greater) of the user entered value and the lower (upper) limit of the tabular data. When linearly interpolating tabular data, the limits of the data set are used unless the user entered maximum is more restrictive (e.g., 64 W in this example is not more restrictive than the data set).

For the resulting curve object, the calculated coefficients may not perfectly represent the data set (i.e., in this example coefficient 1, 2, and 3 should have been 0). Duplicating the 0,0 data pair four additional times (to weight the 0 crossing) yields constant coefficients of 0. This could also be changed manually in the curve object created by the program.

Referring to Figure [fig:fan-power-ratio-example], a selection of LinearInterpolationOfTable would interpolate the tabular data within the limits of the data set (blue circles) resulting in a maximum X and Curve value of 0.8 and 0.512 (i.e., 64/125), respectively. Selecting EvaluateCurveToLimits allows extrapolation of the data set up to a power ratio of 1 had 125 W been entered as the maximum table output in this example.

In the graph below, the linearly interpolated tabular data (blue line) represent a less accurate fan power ratio curve than the performance curve itself (red line). In this specific example, it is more accurate to rely on the performance curve results (i.e., Interpolation Type = EvaluateCurveToLimits in table object). In addition, the performance curve is able to extrapolate outside the limits of the data set since the regression analysis provides a smooth continuous curve through 1. Selecting the LagrangeInterpolationLinearExtrapolation interpolation method with a cubic curve type is similar to the performance curve results.

Including additional data in the table object (e.g., data points for flow fractions = 0.4 and 1) would allow direct linear interpolation of the tabular data without significant loss of accuracy compared to the performance curve or lagrange methods.

Curve output in eio file (when using Output:Diagnostics, DisplayAdvancedReportVariables):

Tables based on two independent variables[LINK]

The tabular data entered for polynomials with two independent variables represent x, y and output data pairs as described in the previous section for performance curves. The x and y in each of the previous equations represent the independent variables (model inputs) and the output represents the dependent variable. The data pairs are organized as the data points for the independent variables followed by the data point for the dependent variable. The order of the data is significant in that the x and y data are entered in the same order as shown in the model’s fundamental equation. The data pairs form a two-dimensional array that may either be linearly interpolated, interpolated using a second order polynomial, or this data may be used to calculate the equation coefficients (a-f) as described in the previous section.

The equation order or degree is user selected as biquadratic or quadraticlinear. This choice determines: 1) where this table object may be used (i.e., certain objects may required a specific form of the equation), and 2) the fundamental equation used to calculate the regression coefficients. The following example describes the methodology used when tabular input data is used in place of common performance curve objects.

Given a generic manufacturer’s air conditioner data for an AC system having a rated total cooling capacity of 7735.1 W, the change in capacity is shown in the table to be a function of both cooling coil entering air wet-bulb temperature and condenser entering air dry-bulb temperature. The tabular data is entered as the actual cooling capacity and will be normalized by the program according to the rated capacity of 7735.1 W. The cooling coil EIR curve could be developed in a similar fashion, except that EIR (Power/TotCap) must first be calculated from the tabular data below BEFORE entering this data into a table object. In this example shown in Figure [fig:generic-manufacturers-normalized-capacity-example], only data highlighted in yellow will be used.

The tabular data can be entered directly into a table object. As an example, for an air-cooled DX cooling coil object in EnergyPlus, the capacity as a function of temperature has the following fundamental equation (Ref. Single-Speed Electric DX Air Cooling Coil):

TotCapTempModFac=a+b(Twb,i)+c(Twb,i)2+d(Tc,i)+e(Tc,i)2+f(Twb,i)(Tc,i)

where:

Twb,i is the wet-bulb temperature of the air entering the cooling coil (∘C)

Tc,i is the dry-bulb temperature of the air entering an air-cooled condenser (∘C).

Given this form of the fundamental equation, the data pairs for the cooling coil are entered as entering air wet-bulb temperature, condenser entering dry-bulb temperature, and total cooling capacity. These 3 values, in this precise order, make up each data pair. As this example describes how the DX coil cooling capacity changes with changes in indoor and outdoor temperature, the curve type selected is BiQuadratic and, therefore, the minimum number of data pairs equals 6 (i.e., number of coefficients in the equation above). Evaluating this tabular data based on regression coefficients may be less desirable to the user since the data in the lower right corner of the table is somewhat flat due to controls or other hardware constraints. For the sake of this example, the regression analysis is chosen. In this example, the DX cooling coil total cooling capacity at the ARI rating point is used to normalize the capacity data (e.g., 7735.1 W at 19.4∘C EWB and 35∘C outdoor dry-bulb temperature). In addition, the minimum and maximum limits are chosen such that extrapolation of the performance curve is allowed. Notice in the example below that:

The data pairs do not need to be entered in ascending order, this data set will automatically be re-ordered in ascending order by the program.

As shown in the table object below, only three of the five entries for entering air wet-bulb temperature were entered in the table object and therefore used for the regression analysis. This data entry technique may save time when entering a large data set, however, it may have unforeseen consequences on the resulting regression coefficients (i.e., the coefficients may provide less accuracy than desired). Note in the figure below the difference between the manufacturers data at 19.4∘C entering air wet-bulb temperature vs the prediction made by the regression coefficients. Since this data set (i.e., the 4 data points at 19.4∘C entering air wet-bulb temperature from the table above) was left out of the regression analysis, the predicted capacity at this condition is slightly under-estimated.

The minimum and maximum table output entered by the user uses the same units as the output values and are subsequently normalized in the same manner as the dependent variable in the data pairs.

For the resulting curve object, the minimum (maximum) limits are based on the lesser (greater) of the user entered value and the lower (upper) limit of the tabular data. When linearly interpolating tabular data, only the limits of the data set are used.

For the resulting curve object, the calculated coefficients may not perfectly represent the entire data set since all data was not used (i.e., in this example the regressed data do not line up exactly with all the manufacturers data, however, do line up well with the data included in the table object).

Selecting LinearInterpolationOfTable would interpolate the tabular data within the limits of the data set (characters) resulting in a maximum X1, X2 and Curve value of 22.2, 40.8 and 1.25 (i.e., 9206.0/7375.1), respectively. Note how these maximum values compare to the maximum values in the generated curve object below which chose the EvaluateCurveToLimits option instead (i.e., the user min/max inputs were used to generate these fields when creating the curve object). The minimum values would be affected in a similar manner. Selecting Lagrange or EvaluateCurveToLimits allows extrapolation of the data set to values specified by the user.

In the graph below, the linearly interpolated tabular data (character data set representing manufacturers data) may better represent the capacity ratio than the performance curve (lines representing the regressed data) given the non-linear relationship between capacity and temperature shown in the table and/or graph. However, extrapolation of the data set is performed linearly and the second order affects of temperature would be lost when extrapolating. Either the data set would be expanded to include other relevant data (e.g., data at colder outdoor temperatures where cooling may be required) which could then be interpolated or additional existing data could be added to the table object to allow more accurate regression coefficients to be used to predict data outside the table data limits.

Curve output in eio file (when using Output:Diagnostics, DisplayAdvancedReportVariables):

Lookup Tables[LINK]

Lookup tables provide a method to evaluate a group of data that may or may not conform to a fundamental equation. Only tabular data which conform to existing performance curve equations are currently allowed (i.e., that lookup table name is entered where any valid performance curve is allowed therefore the table data must conform to the models fundamental equation for that specific curve). Efforts to include this lookup table in the energy management system would allow custom use of lookup tables, however, calling lookup tables from the EMS system is not currenly possible. Lookup tables can interpolate the actual data using a non-linear polynomial equation (order higher than 1). As with other table or curve objects, the lookup table can be used anywhere a valid curve object name is allowed. Care must be taken to ensure the table data format is consistent with the associate model that is using the performance curve (e.g., DX cooling coil capacity as a function of temperature where independent variable X1 = indoor wet-bulb temperature and independent variable X2 = outdoor dry-bulb temperature).

The lookup tables are evaluated using the Lagrange form of the interpolation polynomial or the previously described interpolation methods of LinearInterpolationOfTable and EvaluateCurveToLimits. When using the Lagrange method, the number of points used in the interpolation is equal to 1 plus the polynomial order (e.g., a second order interpolation would use 3 points).

pn(x)=n∑i=0yili(x)

li(x)=Πj≠i(x−xjxi−xj)i=0,1,...,n

First-order Lagrange interpolation polynomial:

p1(x)=(x−x1)(x0−x1)y0+(x−x0)(x1−x0)y1

Second-order Lagrange interpolation polynomial:

p2(x)=(x−x1)(x−x2)(x0−x1)(x0−x2)y0+(x−x0)(x−x2)(x1−x0)(x1−x2)y1+(x−x0)(x−x1)(x2−x0)(x2−x1)y2

Third-order Lagrange interpolation polynomial:

p3(x)=(x−x1)(x−x2)(x−x3)(x0−x1)(x0−x2)(x0−x3)y0+(x−x0)(x−x2)(x−x3)(x1−x0)(x1−x2)(x1−x3)y1+(x−x0)(x−x1)(x−x3)(x2−x0)(x2−x1)(x2−x3)y2+(x−x0)(x−x1)(x−x2)(x3−x0)(x3−x1)(x3−x2)y3

where:

x is the interpolation point

xn is the x value of tabular data

yn is the y value of tabular data

pi(n) is the polynomial (table) output.

The lookup table is interpolated using the interpolation polynomial shown above. If the table input value (interpolation point) is near the bottom edge or exceeds the table boundaries, a linear extrapolation is used (2-point extrapolation). The interpolation order is determined by the user entered number of interpolation points.

A regression analysis may be performed on any lookup table having one or two indpenedent variables. As with performance tables, the resulting performance curve coefficients are calculated and used in the simulation only when the interpolation method is selected as EvaluateCurveToLimits. In addition, the performance curve is only written to the eio file when the output diagnostics flag is set to DisplayAdvancedReportVariables (ref. Output:Diagnostics, DisplayAdvancedReportVariables).

Using the example provided in the section above for Tables based on two indpendent variables, the lookup table object would be defined as follows:

Documentation content copyright © 1996-2018 The Board of Trustees of the University of Illinois and the Regents of the University of California through the Ernest Orlando Lawrence Berkeley National Laboratory. All rights reserved. EnergyPlus is a trademark of the US Department of Energy.

This documentation is made available under the EnergyPlus Open Source License v1.0.