Group Heating and Cooling Coils[LINK]

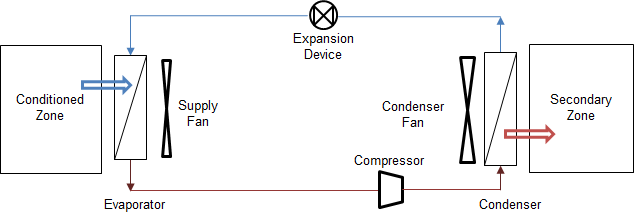

Several different coils may be added to zone equipment and air loops. This includes simple heating (gas, electric, and hot water) and a simple water-cooling coil as well as a more detailed flat fin water-cooling coil model. In general, the heating coil description can be used for a heating coil, a reheat coil, or a preheat coil in the air loop simulation or for zone equipment. Figure [fig:example-air-loop-heating-cooling-coil] is an example of a heating and cooling coil in the air loop simulation in a dual duct system. This does show the basic node structure that will be referenced in the input description. The figure does show water coils since they are the most complex to input in the simulation compared to the Electric and Gas coils which only have air connections.

![Example Air Loop Heating & Cooling Coil [fig:example-air-loop-heating-cooling-coil]](media/image349.png)

Coil:Cooling:Water[LINK]

The water cooling coil (Coil:Cooling:Water) has the ability to give detailed output with simplified inputs, inputting complicated coil geometry is not required by the user for this model instead the coil is sized in terms of auto-sizeable thermodynamic inputs. The coil requires thermodynamic inputs such as temperatures, mass flow rates and humidity ratios.

The coil is sized using auto-sized/user design input conditions and the UA values are calculated from the design conditions. A rough estimate of the coil area is provided along with percentage of surface wet and/or dry. This model uses the NTU-effectiveness approach to model heat transfer and has two types of flow arrangements cross-flow or counter-flow.

The basic underlying idea is - use auto sizable thermodynamic design inputs, calculate the coil UA s, use these UA values and operating conditions from the nodes connections, calculate the outlet stream conditions, and calculate the heat transfer rates.

See section Cooling Coil Model in the EnergyPlus Engineering Document for further details regarding this model.

A unique user-assigned name for an instance of a cooling coil. Any reference to this cooling coil by another object will use this name.

Field:Availability Schedule Name[LINK]

Schedule that defines when the coil is available. The name of the schedule (ref: Schedule) that denotes whether the cooling coil can run during a given time period. A schedule value greater than 0 (usually 1 is used) indicates that the unit can be on during a given time period. A value less than or equal to 0 (usually 0 is used) denotes that the unit is off. If this field is blank, the schedule has a value of 1 for all time periods.

Field: Design Water Flow Rate[LINK]

The maximum possible water volume flow rate (m3/sec) through the coil. This is an auto sizable design input.

Field: Design Air Flow Rate[LINK]

The maximum possible air volume flow rate (m3/sec) through the coil. This is an auto sizable design input.

Field: Design Inlet Water Temperature[LINK]

The inlet water temperature for the design flow (C). This is an auto sizable design input.

Field: Design Inlet Air Temperature[LINK]

The inlet air temperature for the design flow (C). This is an auto sizable design input.

Field: Design Outlet Air Temperature[LINK]

The outlet air condition desired for design flow (C). This is an auto sizable design input.

Field: Design Inlet Air Humidity Ratio[LINK]

The highest value of humidity ratio possible for the Design inlet air stream (kgWater/kgDryAir). This is an auto sizable input.

Field: Design Outlet Air Humidity Ratio[LINK]

The value of humidity ratio for the Design outlet air stream (kgWater/kgDryAir), it is an auto sizable input.

Field: Water Inlet Node Name[LINK]

The name of the water coil inlet from the chilled water loop, i.e. Cooling Coil Water Inlet Node. It is from this node the operating inputs for water are transferred to the coil.

Field: Water Outlet Node Name[LINK]

The name of the water coil outlet from the chilled water loop, i.e. Cooling Coil Water Outlet Node. It is from this node the operating output for water are reported to the coil.

Field: Air Inlet Node Name[LINK]

The name of the air inlet to the water coil, i.e. Cooling Coil Air Inlet Node. It is from this node the operating inputs for air are transferred to the coil.

Field: Air Outlet Node Name[LINK]

The name of the air outlet from the water coil, i.e. Cooling Coil Air Outlet Node. It is from this node the operating output for airside is reported to the coil.

Field: Type of Analysis[LINK]

The coil has two modes of operation, termed as SimpleAnalysis and DetailedAnalysis. The difference between the two modes being, the simple mode reports the value of surface area fraction wet of the coil as dry or wet. The detailed mode give the exact value, however the execution time in detailed mode is noticeably higher.

Field: Heat Exchanger Configuration[LINK]

The coil is operable in two modes, Cross Flow for general A/C applications and Counter Flow mode. Air-conditioning systems generally use cross flow heat exchangers. The default is set to Counter Flow mode.

Field: Condensate Collection Water Storage Tank Name[LINK]

This field is optional. It is used to describe where condensate from the coil is collected. If blank or omitted, then any coil condensate is discarded. Enter the name of Water Storage Tank object defined elsewhere and the condensate will then be collected in that tank.

Field: Design Water Temperature Difference[LINK]

This input field is optional. If specified, it is used for sizing the Design Water Flow Rate. If blank or omitted, the Loop Design Temperature Difference value specified in Sizing:Plant object is used for sizing the Design Water Flow Rate.

Examples when auto sized in an IDF are as below:

Coil:Cooling:Water,

Main Cooling Coil 1, !- Coil Name

CoolingCoilAvailSched, !-Availability Schedule Name

autosize, !- Design Water Volume Flow Rate of Coil {m3/s}

autosize, !- Design Air Flow Rate of Coil {m3/s}

autosize, !- Design Inlet Water Temperature {C}

autosize, !- Design Inlet Air Temperature {C}

autosize, !- Design Outlet Air Temperature {C}

autosize, !- Design Inlet Air Humidity Ratio(kgWater/kgDryAir)

autosize, !- Design Outlet Air Humidity Ratio(kgWater/kgDryAir)

Main Cooling Coil 1 Water Inlet Node, !- Coil_Water_Inlet_Node

Main Cooling Coil 1 Water Outlet Node, !- Coil_Water_Outlet_Node

Mixed Air Node 1, !- Coil_Air_Inlet_Node

Main Cooling Coil 1 Outlet Node; !- Coil_Air_Outlet_Node

Examples when values (hard-sized) are input in an IDF are as below:

Coil:Cooling:Water,

Main Cooling Coil 1, !- Coil Name

CoolingCoilAvailSched, !-Availability Schedule Name

0.0022, !- Design Water Volume Flow Rate of Coil {m3/s}

1.45, !- Design Air Flow Rate of Coil {m3/s}

6.1, !- Design Inlet Water Temperature {C}

25, !- Design Inlet Air Temperature {C}

10, !- Design Outlet Air Temperature {C}

0.012, !- Design Inlet Air Humidity Ratio

0.008, !- Design Outlet Air Humidity Ratio

Main Cooling Coil 1 Water Inlet Node, !- Coil_Water_Inlet_Node

Main Cooling Coil 1 Water Outlet Node, !- Coil_Water_Outlet_Node

Mixed Air Node 1, !- Coil_Air_Inlet_Node

Main Cooling Coil 1 Outlet Node; !- Coil_Air_Outlet_Node

Following are the list of possible output output variables from this coil model:

HVAC,Sum,Cooling Coil Total Cooling Energy [J]

HVAC,Sum,Cooling Coil Sensible Cooling Energy [J]

HVAC,Average,Cooling Coil Total Cooling Rate [W]

HVAC,Average,Cooling Coil Sensible Cooling Rate [W]

HVAC,Average,Cooling Coil Wetted Area Fraction []

HVAC,Average,Cooling Coil Condensate Volume Flow Rate [m3/s]

HVAC,Sum,Cooling Coil Source Side Heat Transfer Energy [J]

HVAC,Sum,Cooling Coil Condensate Volume [m3]

Cooling Coil Total Cooling Energy (J)[LINK]

Cooling Coil Total Cooling Energy is the total amount of heat transfer taking place in the coil at the operating conditions.

Cooling Coil Sensible Cooling Energy (J)[LINK]

Cooling Coil Sensible Cooling Energy is the total amount of Sensible heat transfer taking place in the coil at the operating conditions. It only takes into account temperature difference in the inlet and outlet air streams at operating conditions.

Cooling Coil Total Cooling Rate (W)[LINK]

Cooling Coil Total Cooling Rate is the Rate of heat transfer taking place in the coil at the operating conditions. The units are (J/sec) or Watts.

Cooling Coil Sensible Cooling Rate (W)[LINK]

Cooling Coil Sensible Cooling Rate is the Rate of Sensible heat transfer taking place in the coil at the operating conditions.

Cooling Coil Wetted Area Fraction [][LINK]

It defines the fraction of total surface area of coil which is wet due to moisture condensation on the surface of the coil. Value varies between 0.0 and 1.0.

In addition, if a Water Storage Tank is used to collect coil condensate, then the following outputs will be available.

Cooling Coil Condensate Volume Flow Rate [m3/s][LINK]

Cooling Coil Condensate Volume [m3][LINK]

These reports provide the rate and amount of condensate from the coil. Condensate is water condensed out of the air as a result of cooling. The condensate volume is also reported on the meter for OnSiteWater.

Cooling Coil Source Side Heat Transfer Energy [J][LINK]

This is the energy extracted from the chilled water serving the coil, in Joules.

Coil:Heating:Water[LINK]

This simple heating coil model only does sensible heating of the air. The simple heating coil uses the Effectiveness-NTU algorithm and assumes a cross-flow heat exchanger.

A unique identifying name for each coil.

Field:Availability Schedule Name[LINK]

Schedule that defines when the coil is available. A schedule value greater than 0 (usually 1 is used) indicates that the unit can be on during a given time period. A value less than or equal to 0 (usually 0 is used) denotes that the unit is off. If this field is blank, the schedule has a value of 1 for all time periods.

Field: U-Factor Times Area Value[LINK]

The UA value for the coil needed for the Effectiveness-NTU heat exchanger model. An estimate of the UA can be obtained from:

q=UA×(Twater,avg−Tair,avg)

where q is the heat transferred from water to the air in watts; Twater,avg is the average water temperature in degrees C; and Tair,avg is the average air temperature in degrees C. Or the LMTD temperature difference can be used. This field is used when Performance Input Method = UFactorTimesAreaAndDesignWaterFlowRate.This field is autosizable.

Field: Maximum Water Flow Rate[LINK]

The maximum possible water flow rate (m3/sec) through the coil. This field is used when Coil Performance Input Method = UFactorTimesAreaAndDesignWaterFlowRate. This field is autosizable.

Field: Water Inlet Node Name[LINK]

The name of the coil s water inlet node from the hot water loop.

Field: Water Outlet Node Name[LINK]

The name of the coil s water outlet node from the hot water loop.

Field: Air Inlet Node Name[LINK]

The name of the air inlet node to the water coil.

Field: Air Outlet Node Name[LINK]

The name of the air outlet node from the water coil.

The user can choose either UFactorTimesAreaAndDesignWaterFlowRate or NominalCapacity. If UFactorTimesAreaAndDesignWaterFlowRate is selected, the user must input values for UA of the Coil and Max Water FlowRate of the Coil (and Rated Capacity is ignored). If NominalCapacity is chosen, the user must input a Rated Capacity for the coil; UA of the Coil and Max Water FlowRate of the Coil will be ignored. Rated capacity is defined as the heating capacity in watts of the coil at the rating points (i.e., the rated inlet and outlet water/air temperatures defined in the input fields below). The rated capacity is used to calculate a water mass flow rate and a UA for the coil. The default is NominalCapacity.

To autosize the capacity, choose UfactorTimesAreaAndDesignWaterFlowRate and put autosize as the inputs for U-Factor Times Area Value, Maximum Water Flow Rate, and Rated Capacity. The program will use the Sizing inputs to size the coil. The rated temperatures (see below) are ignored in autosizing. These are used only when the user is specifying coil performance using the NominalCapacity input method.

Field: Gross Rated Heating Capacity[LINK]

The heating capacity of the coil in watts at the rated inlet and outlet air and water temperatures. The gross rated heating capacity does not account for the effect of supply air fan heat. This field is used when the Performance Input Method = Nominal Capacity. This field is autosizable. The rating points are given in the four subsequent input fields.

Field: Rated Inlet Water Temperature[LINK]

The inlet water temperature (degrees C) corresponding to the rated heating capacity. The default is 82.2 degrees C (180 degrees F).

Field: Rated Inlet Air Temperature[LINK]

The inlet air temperature (degrees C) corresponding to the rated heating capacity. The default is 16.6 degrees C (60 degrees F).

Field: Rated Outlet Water Temperature[LINK]

The outlet water temperature (degrees C) corresponding to the rated heating capacity. The default is 71.1 degrees C (160 degrees F).

Field: Rated Outlet Air Temperature[LINK]

The outlet air temperature (degrees C) corresponding to the nominal heating capacity. The default is 32.2 degrees C (90 degrees F).

Field: Rated Ratio for Air and Water Convection[LINK]

This is the ratio of convective heat transfers between air side and water side of the heating coil at the rated operating conditions. The default is .5. This ratio describes the geometry and the design of the coil and is defined by:

ratio=ηf(hA)air(hA)water

where,

ηf is the fin efficiency, (dimensionless)

h is the surface convection heat transfer coefficient

A is the surface area

Field: Design Water Temperature Difference[LINK]

This input field is optional. If specified, it is used for sizing the Design Water Flow Rate. If blank or omitted, the Loop Design Temperature Difference value specified in Sizing:Plant object is used for sizing the Design Water Flow Rate.

An example input of the object is:

Coil:Heating:Water,

SPACE3-1 Zone Coil, !- Coil Name

ReheatCoilAvailSched, !- Availability Schedule Name

, !- UA of the Coil {W/K}

, !- Max Water Flow Rate of Coil {m3/s}

SPACE3-1 Zone Coil Water In Node, !- Coil_Water_Inlet_Node

SPACE3-1 Zone Coil Water Out Node, !- Coil_Water_Outlet_Node

SPACE3-1 Zone Coil Air In Node, !- Coil_Air_Inlet_Node

SPACE3-1 In Node, !- Coil_Air_Outlet_Node

NominalCapacity, !- Coil Performance Input Method

10000., !- Gross Rated Heating Capacity

0.55; !- Rated Ratio for Air and Water Convection

HVAC,Sum, Heating Coil Heating Energy [J]

HVAC,Sum,Heating Coil Source Side Heat Transfer Energy [J]

HVAC,Average,Heating Coil Heating Rate [W]

HVAC,Average, Heating Coil U Factor Times Area Value [W/K]

Heating Coil Heating Energy [J][LINK]

Heating Coil Heating Energy is the total amount of heat transfer taking place in the coil at the operating conditions.

Heating Coil Heating Rate [W][LINK]

Heating Coil Heating Rate is the Rate of heat transfer taking place in the coil at the operating conditions. The units are (J/sec) or Watts.

Heating Coil U Factor Times Area Value [W/K][LINK]

This characterizes the overall heat transfer UA value, or U-factor times Area. The simple heating coil model adjusts UA value based on inlet temperatures and flow rates and this output contains the results from that adjustment.

Heating Coil Source Side Heat Transfer Energy [J][LINK]

This is the same has the Heating Coil Heating Energy but it is also metered as a plant loop heating demand. This represents the heat in Joules extracted from the hot water serving the coil.

Coil:Heating:Steam[LINK]

The simple steam to air heating coil model only does sensible heating of the air. The steam to air coils condenses the steam and sub cools steam at loop pressure and discharges the condensate through steam traps at low pressure condensate line.

A unique identifying name for each steam coil.

Field:Availability Schedule Name[LINK]

Schedule that defines when the coil is available. If the schedule s value is less than or equal to 0.0, then the coil is not available and flow will not be requested. If the schedule s value is > 0.0 (usually 1 is used), the coil is available. If this field is blank, the schedule has values of 1 for all time periods.

Field: Maximum Steam Flow Rate[LINK]

The maximum possible steam volumetric flow rate in m3/s through the steam heating coil. The steam volumetric flow rate is calculated at 100C and 101325 Pa. This field is autosizable.

Field: Degree of SubCooling[LINK]

Ideally the steam trap located at the outlet of steam coil should remove all the condensate immediately, however there is a delay in this process in actual systems which causes the condensate to SubCool by certain degree in the coil before leaving the coil, this SubCool occurs in the steam coil and this SubCool-heat is added to the zone. The minimum value is 2 ° Celsius and default is 5 ° Celsius.

Field: Degree of Loop SubCooling[LINK]

This essentially represents the heat loss to the atmosphere due to uninsulated condensate return piping to the boiler. Condensate return piping operates at atmospheric pressure and is not insulated. The condensate sub cools to certain degree before it is pumped back to the boiler. The minimum value is 10 ° Celsius and default is 20 ° Celsius.

Field: Water Inlet Node Name[LINK]

The name of the steam coil inlet from the steam loop, i.e. Steam Coil steam inlet node.

Field: Water Outlet Node Name[LINK]

The name of the steam coil outlet to the condensate loop, i.e. Steam Coil condensate outlet node.

Field: Air Inlet Node Name[LINK]

The name of the air inlet to the steam coil, i.e. Steam Coil Air Inlet Node.

Field: Air Outlet Node Name[LINK]

The name of the air outlet from the steam coil, i.e. Steam Coil Air Outlet Node.

Field:Coil Control Type[LINK]

Choice of either ZoneLoadControl steam coil or TemperatureSetpointControl steam coil. A zone coil is load controlled and an air loop steam coil is temperature controlled.

Field: Temperature Setpoint Node Name[LINK]

If the coil is used in the air loop simulation and is temperature controlled using a Set Point Manager (i.e., the previous file is TemperatureSetpointConrtol), then the node that is the control node needs to be specified here. If the coil is used in an air terminal unit, the coil is load controlled and a control node set point is not required (i.e., the previous field is ZoneLoadControl).

An example of a Steam Coil input statement (one each for Temperature Controlled and Load Controlled) from an IDF is given below:

Coil:Heating:Steam,

VAV SYS 1 Heating Coil, !- Coil Name

ReheatCoilAvailSched, !- Availability Schedule Name

0.06, !- Max Steam volume Flow rate

5.0, !- Deg of Subcooling Desired

15.0, !- Loop Subcooling Desired

VAV SYS 1 Heating Coil Steam Inlet, !- Coil Steam Inlet Node

VAV SYS 1 Heating Coil Steam Outlet, !- Coil Water Outlet Node

VAV SYS 1 Cooling Coil Outlet, !- Coil Air Inlet Node

VAV SYS 1 Heating Coil Outlet, !- Coil Air Outlet Node

TemperatureSetPointControl, !- field Coil Control Type

VAV SYS 1 Heating Coil Outlet; !- field Coil Temp Setpoint Node

Coil:Heating:Steam,

SPACE1-1 Reheat Coil, !- Coil Name

ReheatCoilAvailSched, !- Availability Schedule Name

autosize, !- Max Steam volume Flow rate

5.0, !- Deg of Subcooling Desired

15.0, !- Loop Subcooling Desired

SPACE1-1 Reheat Coil Steam Inlet, !- Coil Steam Inlet Node

SPACE1-1 Reheat Coil Steam Outlet, !- Coil Water Outlet Node

SPACE1-1 Damper Outlet, !- Coil Air Inlet Node

SPACE1-1 Supply Inlet, !- Coil Air Outlet Node

ZoneLoadControl; !- field Coil Control Type

Heating Coil (Steam) Outputs:[LINK]

HVAC,Sum, Heating Coil Heating Energy [J]

HVAC,Average,Total Steam Coil Heating Rate [W]

HVAC,Average,Heating Coil Steam Trap Loss Rate [W]

HVAC, Average, Heating Coil Steam Inlet Temperature [C]

HVAC, Average, Heating Coil Steam Outlet Temperature [C]

HVAC, Average, Heating Coil Steam Mass Flow Rate [kg/s]

Heating Coil Heating Energy [J][LINK]

Heating Coil Heating Energy is the total amount of heat transfer taking place in the coil at the operating conditions.

Heating Coil Heating Rate [W][LINK]

Heating Coil Heating Rate is the Rate of heat transfer taking place in the coil at the operating conditions. The units are (J/sec) or Watts.

Heating Coil Steam Trap Loss Rate [W][LINK]

Loop losses represent the unavoidable loss due to degree of sub cooling in the condensate return piping back to the boiler and the loss occurring due to flashing of steam across the steam trap due to pressure differential between the steam and the condensate side.

Heating Coil Steam Inlet Temperature [C][LINK]

Heating Coil Steam Outlet Temperature [C][LINK]

Heating Coil Steam Mass Flow Rate [kg/s][LINK]

These outputs are the Steam inlet and condensate outlet temperatures and steam flow rate for the boiler.

Coil:Heating:Electric[LINK]

The electric heating coil is a simple capacity model with a user-inputted efficiency. In many cases, this efficiency for the electric coil will be 100%. This coil will be simpler than shown in Figure [fig:example-air-loop-heating-cooling-coil] since it will only have air nodes to connect it in the system. The coil can be used in the air loop simulation or in the zone equipment as a reheat coil. Depending on where it is used determines if this coil is temperature or capacity controlled. If used in the air loop simulation it will be controlled to a specified temperature scheduled from the SetPoint Manager. If it is used in zone equipment, it will be controlled from the zone thermostat by meeting the zone demand.

A unique identifying name for each coil.

Field:Availability Schedule Name[LINK]

Schedule that defines when the coil is available. If the schedule s value is 0.0, then the coil is not available and flow will not be requested. If the schedule s value is > 0.0 (usually 1 is used), the coil is available. If this field is blank, the schedule has values of 1 for all time periods. Schedule values must be > = 0 and < = 1.

Field: Efficiency[LINK]

This is user-inputted efficiency (decimal units, not percent) and can account for any loss. In most cases for the electric coil, this will be 100%.

Field: Nominal Capacity[LINK]

This is the maximum capacity of the coil (W). This controlled coil will only provide the needed capacity to meet the control criteria whether it is temperature or capacity controlled. This field is autosizable.

Field: Air Inlet Node Name[LINK]

The name of the air inlet to the electric coil, i.e. Heating Coil Air Inlet Node.

Field: Air Outlet Node Name[LINK]

The name of the air outlet from the electric coil, i.e. Heating Coil Air Outlet Node.

Field: Temperature Setpoint Node Name[LINK]

If the coil is used in the air loop simulation and is temperature controlled using a Set Point Manager, then the node that is the control node needs to be specified here. If the coil is used in an air terminal unit, the coil is load controlled and a control node set point is not required.

An example of IDF usage:

Coil:Heating:Electric,

AHU Reheater, !- Name

2, !- Availability Schedule Name

0.99, !- Efficiency

600000, !- Nominal Capacity {W}

DOAS Supply Fan Outlet, !- Air Inlet Node Name

AHU Reheater Outlet, !- Air Outlet Node Name

AHU Reheater Outlet; !- Temperature Setpoint Node Name

HVAC,Sum,Heating Coil Heating Energy [J]

HVAC,Average,Heating Coil Heating Rate [W]

HVAC,Sum,Heating Coil Electric Energy [J]

HVAC,Average,Heating Coil Electric Power [W]

Heating Coil Heating Energy (J)[LINK]

Heating Coil Heating Energy is the total amount of heat transfer taking place in the coil at the operating conditions.

Heating Coil Heating Rate [W][LINK]

Heating Coil Heating Rate is the Rate of heat transfer taking place in the coil at the operating conditions. The units are (J/sec) or Watts.

Heating Coil Electric Energy [J][LINK]

Heating Coil electric consumption after the efficiency of the coil has been taken into account in Joules for the timestep reported.

Heating Coil Electric Power [W][LINK]

This field is the average Heating Coil electric power after the efficiency of the coil has been taken into account in Watts for the timestep reported.

Coil:Heating:Electric:MultiStage[LINK]

The multi stage electric heating coil is a simple capacity model with a user-inputted efficiencies at different stages. In many cases, the efficiencies for the electric coil will be 100%. This coil will only have air nodes to connect it in the system. The coil can be used in the air loop simulation or in the zone equipment as a reheat coil. Depending on where it is used determines if this coil is temperature or capacity controlled. If used in the air loop simulation it will be controlled to a specified temperature scheduled from the SetPoint Manager. If it is used in zone equipment, it will be controlled from the zone thermostat by meeting the zone demand. For the time being, this coil model can only be called by the parent object AirLoopHVAC:UnitaryHeatPump:AirToAir:MultiSpeed.

A unique identifying name for each coil.

Field:Availability Schedule Name[LINK]

Schedule that defines when the coil is available. If the schedule s value is 0.0, then the coil is not available and flow will not be requested. If the schedule s value is > 0.0 (usually 1 is used), the coil is available. If this field is blank, the schedule has values of 1 for all time periods. Schedule values must be > = 0 and < = 1.

Field: Air Inlet Node Name[LINK]

The name of the air inlet to the electric coil, i.e. Heating Coil Air Inlet Node.

Field: Air Outlet Node Name[LINK]

The name of the air outlet from the electric coil, i.e. Heating Coil Air Outlet Node.

Field: Temperature Setpoint Node Name[LINK]

If the coil is used in the air loop simulation and is temperature controlled using a Set Point Manager, then the node that is the control node needs to be specified here. If the coil is used in an air terminal unit, the coil is load controlled and a control node set point is not required. At present, the multistage electric heating coil does not model temperature setoint control.

Field: Stage 1 Efficiency[LINK]

This is stage 1 user-inputted efficiency (decimal units, not percent) and can account for any loss. In most cases for the electric coil, this will be 100%.

Field: Stage 1 Nominal Capacity[LINK]

This is stage 1 capacity of the coil (W). This field is autosizable.

Field: Stage 2 Efficiency[LINK]

This is stage 2 user-inputted efficiency (decimal units, not percent) and can account for any loss. In most cases for the electric coil, this will be 100%.

Field: Stage 2 Nominal Capacity[LINK]

This is stage 2 capacity of the coil (W). This field is autosizable.

Field: Stage 3 Efficiency[LINK]

This is stage 3 user-inputted efficiency (decimal units, not percent) and can account for any loss. In most cases for the electric coil, this will be 100%.

Field: Stage 3 Nominal Capacity[LINK]

This is stage 3 capacity of the coil (W). This field is autosizable.

Field: Stage 4 Efficiency[LINK]

This is stage 4 user-inputted efficiency (decimal units, not percent) and can account for any loss. In most cases for the electric coil, this will be 100%.

Field: Stage 4 Nominal Capacity[LINK]

This is stage 4 capacity of the coil (W). This field is autosizable.

An example in IDF form:

Coil:Heating:Electric:MultiStage,

Heat Pump Heating Coil 1, !- Name

FanAndCoilAvailSched, !- Availability Schedule Name

Heating Coil Air Inlet Node, !- Air Inlet Node Name

SuppHeating Coil Air Inlet Node, !- Air Outlet Node Name

, !- Temp Setpoint node name

3, !- Number of Stages

1, !- Stage 1 Efficiency

Autosize, !- Stage 1 Nominal Capacity {W}

1, !- Stage 2 Efficiency

Autosize, !- Stage 2 Nominal Capacity {W}

1, !- Stage 3 Efficiency

Autosize; !- Stage 3 Nominal Capacity {W}

HVAC,Sum,Heating Coil Heating Energy[J]

HVAC,Average,Heating Coil Heating Rate[W]

HVAC,Sum,Heating Coil Electric Consumption [J]

HVAC,Average,Heating Coil Electric Power [W]

Heating Coil Heating Energy (J)[LINK]

Heating Coil Heating Energy is the total amount of heat transfer taking place in the coil at the operating conditions.

Heating Coil Heating Rate[W][LINK]

Heating Coil Heating Rate is the rate of heat transfer taking place in the coil at the operating conditions. The units are (J/sec) or Watts.

Heating Coil Electric Consumption [J][LINK]

Heating Coil electric consumption after the efficiency of the coil has been taken into account in Joules for the timestep reported.

Heating Coil Electric Power [W][LINK]

This field is the average Heating Coil electric power after the efficiency of the coil has been taken into account in Watts for the timestep reported.

Coil:Heating:Desuperheater[LINK]

A simplified approach is used to determine the performance of this air heating coil. The model assumes that the heating energy provided by this coil is reclaimed from the superheated refrigerant gas leaving a compressor (i.e., a desuperheating refrigerant-to-air heating coil) and does not impact the performance of the compressor. This coil can be used in air loop simulations but can t be used by certain compound objects (e.g., AirLoopHVAC:UnitaryHeatPump:AirToAir, AirLoopHVAC:UnitaryHeatPump:WaterToAir, or Dehumidifier:Desiccant:NoFans) or any air distribution equipment (e.g., AirTerminal:SingleDuct:ConstantVolume:Reheat, AirTerminal:SingleDuct:VAV:Reheat, or AirTerminal:SingleDuct:SeriesPIU:Reheat).

The desuperheater heating coil input requires a coil name, an availability schedule, and a heat reclaim recovery efficiency. The reclaim recovery efficiency determines the amount of heat available for use by this heating coil. Approximately 25-30% of the energy rejected by typical refrigeration system condensers is to reduce the superheated refrigerant vapor temperature to the condensing temperature. Recovery efficiencies higher than 30% may cause the refrigerant gas to condense which in turn impacts the performance of the refrigeration system. For this reason, the maximum heat reclaim recovery efficiency for this coil is 30% for most sources of waste heat, including refrigeration compressor racks. The one exception to this 30% limit is a condenser that is part of a detailed refrigeration system. In a detailed refrigeration system, the portion of the rejected heat that lies within the superheated region is explicitly calculated. Therefore, the desuperheater coils supplied by a condenser attached to a detailed refrigeration system are subject to a maximum reclaim recovery efficiency of 90% of the heat within the superheated region.

The next two input items for the desuperheater heating coil are the node names for the inlet and outlet air streams. The following two input fields define the source of heating energy for the coil. This desuperheater heating coil may only be used with direct expansion (DX) cooling or refrigeration equipment. The first of these two inputs is the heating source object type while the second defines the name of the heating source. For proper modeling, the desuperheater heating coil must be placed downstream of a DX cooling coil when reclaiming heat from that cooling coil. Desuperheating heating coil placement is unrestricted when reclaiming heat from a Refrigeration:CompressorRack or Refrigeration:Condenser.

The next input field is optional and defines the set point node name if the desuperheater heating coil is to be controlled based on temperature. When a load-based control scheme is used, this field is left blank. A final optional input is used to model parasitic electric energy use of auxiliary equipment associated with the desuperheater heating coil (e.g., solenoid valve).

This alpha field defines a unique user-assigned name for an instance of a desuperheater heating coil. Any reference to this desuperheater heating coil by another object will use this name.

Field: Availability Schedule Name[LINK]

This alpha field defines the name of the schedule (ref: Schedule) that denotes whether the desuperheater heating coil can run during a given time period. Schedule values must range from 0 to 1. A schedule value greater than 0 indicates that the coil can operate during the time period. A value equal to 0 denotes that the coil must be off for that time period. If this field is blank, the schedule has values of 1 for all time periods.

Field: Heat Reclaim Recovery Efficiency[LINK]

This numeric field defines the ratio of recovered waste heat from the superheated refrigerant gas to the total rejected waste heat from the heating source (as if no heat reclaim occurred). Values can range from 0.0 up to a maximum of 0.9 if the source is a refrigeration condenser and 0.3 for all other waste heat sources. If this input field is left blank, the default value is 0.8 for a refrigeration condenser source type and 0.25 for all other sources.

Field: Air Inlet Node Name[LINK]

This alpha field defines the name of the HVAC system node from which the desuperheater heating coil draws its inlet air.

Field: Air Outlet Node Name[LINK]

This alpha field defines the name of the HVAC system node to which the desuperheater heating coil sends its outlet air.

Field: Heating Source Object Type[LINK]

This alpha field defines the source of superheated refrigerant gas from which the desuperheater heating coil recovers energy. Valid choices are:

When the heating coil source is a DX Coil, the air loop’s supply air fan control mode may be auto fan (cycling fan cycling coil), constant fan, or variable volume. When the heating source is a compressor rack for refrigerated cases or a refrigeration condenser, the supply air fan control mode should be either variable volume or constant fan.

NOTE: Use of the desuperheater heating coil in variable air volume systems should be done with caution since the model assumption of a fixed heat reclaim recovery efficiency may not be valid if the air flow rate over the coil varies significantly.

Field: Heating Source Name[LINK]

This alpha field defines the name of the desuperheater heating coil source (e.g., the name of a specific valid coil (as mentioned in the previous field) which provides waste heat to this desuperheater heating coil).

NOTE: When the heating source is a Refrigeration Compressor rack, the heat rejection location in the Refrigeration:CompressorRack object must be Outdoors . If the compressor rack heat rejection location is Zone , the total amount of heat rejection available for reclaim (e.g., by this desuperheater heating coil) is set to zero by the compressor rack object and the simulation proceeds.

Field: Temperature Setpoint Node Name[LINK]

This optional alpha field defines the name of the HVAC system node used for temperature-based control (e.g., controlling the heating coil s outlet air dry-bulb temperature to a setpoint). If the desuperheater heating coil is temperature controlled through the use of a Set Point Manager, then the control node specified in the Set Point Manager will be entered here. If the desuperheater heating coil is controlled based on a certain heating load to be met (e.g., using this heating coil as part of AirLoopHVAC:Unitary:Furnace:HeatCool for high humidity control), this field should be left blank.

Field: Parasitic Electric Load[LINK]

This optional numeric field defines the parasitic electric load (in Watts) due to control valves or other devices specific to the desuperheater heating coil. The load is applied whenever the coil is heating the air. The model assumes that this electric load is small and does not contribute to heating the air.

Following is an example input for a desuperheater heating coil.

Coil:Heating:Desuperheater,

DesuperheaterCoil, !- Coil Name

FanAndCoilAvailSched, !- Availability Schedule

0.3, !- Heat Reclaim Recovery Efficiency

Cooling Coil Air Outlet Node, !- Coil Air Inlet Node Name

Air Loop Outlet Node, !- Coil Air Outlet Node Name

Coil:Cooling:DX:SingleSpeed, !- Heating Source Type

Furnace ACDXCoil 1, !- Heating Source Name

, !- Coil Temperature Setpoint Node Name

0.1; !- Parasitic Electric Load {W}

HVAC,Average,Heating Coil Heating Rate [W]

HVAC,Sum,Heating Coil Heating Energy [J]

HVAC,Average,Heating Coil Electric Power [W]

HVAC,Sum,Heating Coil Electric Consumption [J]

HVAC,Average,Heating Coil Runtime Fraction []

HVAC,Average,Heating Coil Heating Rate [W]

HVAC,Sum,Heating Coil Heating Energy [J]

HVAC,Average,Heating Coil Electric Power [W]

HVAC,Sum,Heating Coil Electric Energy [J]

HVAC,Average,Heating Coil Runtime Fraction

Heating Coil Heating Rate [W][LINK]

This output is the average heating rate to the air of the desuperheater heating coil in Watts over the timestep being reported. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil.

Heating Coil Heating Energy [J][LINK]

This output is the total heating output to the air of the desuperheater heating coil in Joules over the timestep being reported. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil. This output is also added to a meter with Resource Type = EnergyTransfer, End Use Key = HeatingCoils, Group Key = System (ref. Output:Meter objects).

Heating Coil Electric Power [W][LINK]

This output is the average electric consumption rate for the parasitic load associated with the desuperheater heating coil in Watts.

Heating Coil Electric Energy [J][LINK]

This output is the electric consumption of the desuperheater heating coil parasitic load in Joules for the timestep being reported. This output is also added to a meter with Resource Type = Electricity, End Use Key = Heating, Group Key = System (ref. Output:Meter objects).

Heating Coil Runtime Fraction [][LINK]

This is the runtime fraction of the desuperheater heating coil for the timestep being reported. Since the desuperheater heating coil can only provide heat when the heat source object is active, the runtime fraction of the desuperheater heating coil will always be less than or equal to the runtime fraction of the heat source object.

Coil:Cooling:DX:VariableRefrigerantFlow[LINK]

The variable refrigerant flow (VRF) DX cooling coil model is nearly identical to the single-speed DX cooling coil model (Ref. Coil:Cooling:DX:SingleSpeed). For this reason, an adaptation of the single-speed DX cooling coil model is used to model the variable-speed compression system used in VRF AC systems. The model inputs are quite similar to the input requirements for the single-speed DX cooling coil model, however, the location of a majority of the inputs have been moved to the variable refrigerant flow air conditioner object since multiple DX cooling coils will use the same DX compression system (Ref. AirConditioner:VariableRefrigerantFlow).

Field: Coil Name[LINK]

This alpha field defines a unique user-assigned name for an instance of a VRF DX cooling coil. Any reference to this DX cooling coil by another object will use this name. This cooling coil name must be entered in the AirConditioner:VariableRefrigerantFlow object. No other sytem type uses this specific coil.

Field: Availability Schedule Name[LINK]

This alpha field defines the name of the DX cooling coil availabiltiy schedule. Schedule values of 0 denote the DX cooling coil is off. A schedule value greater than 0 indicates that the coil can operate during the time period. If this field is blank, the schedule has values of 1 for all time periods.

Field: Gross Rated Total Cooling Capacity[LINK]

This numeric field defines the gross rated total cooling capacity of the DX cooling coil in watts at a rating point of 19.44 C indoor wet-bulb temperature and 35 C outdoor dry-bulb temperature. The total cooling capacity should be a gross , i.e., the effect of supply air fan heat NOT accounted for.

Field: Gross Ratio Sensible Heat Ratio[LINK]

This numeric field defines the gross sensible heat ratio (sensible capacity divided by total cooling capacity) of the DX cooling coil at rated conditions. Both the sensible and total cooling capacities used to define the Rated SHR should be gross (i.e., the effect of supply air fan heat is NOT accounted for)

Field: Rated Air Flow Rate[LINK]

The air volume flow rate, in m3 per second, across the DX cooling coil at rated conditions. The rated air volume flow rate should be between 0.00004027 m3/s and 0.00006041 m3/s per watt of rated total cooling capacity (300 to 450 cfm/ton). The gross rated total cooling capacity and gross rated SHR should be performance information for the unit with at this rated air volume flow rate.

Field: Cooling Capacity Ratio Modifier Function of Temperature Curve Name[LINK]

This alpha field defines the cooling capacity ratio modifier as a function of indoor wet-bulb temperature or indoor wet-bulb and outdoor dry-bulb temperatures. The curve is normalized to 1 at 19.44 C indoor wet-bulb temperature and if a biquadratic curve is used also at 35 C outdoor dry-bulb temperature. This curve is a linear, quadratic, or cubic curve if the cooling capacity is solely a function of indoor wet-bulb temperature (i.e., the indoor terminal units weighted average inlet air wet-bulb temperatures). Without specific manufacturers data indicating otherwise, the use of a single independent variable is recommended for this coil type. If, however, the user has reason to believe the cooling capacity is both a function of indoor wet-bulb temperature and outdoor dry-bulb temperature (and has manufacturers data to create the performance curve), a bi-quadratic equation using weighted average indoor wet-bulb temperature and condenser entering air dry-bulb temperature as the independent variables may be used. See the Engineering Reference for more discussion on using this input field.

Field: Cooling Capacity Modifier Curve Function of Flow Fraction Name[LINK]

This alpha field defines the name of a linear, quadratic or cubic performance curve (ref: Performance Curves) that parameterizes the variation of total cooling capacity as a function of the ratio of actual air flow rate across the cooling coil to the rated air flow rate (i.e., fraction of full load flow). The output of this curve is multiplied by the gross rated total cooling capacity and the total cooling capacity modifier curve (function of temperature) to give the gross total cooling capacity at the specific temperature and air flow conditions at which the coil is operating. The curve is normalized to have the value of 1.0 when the actual air flow rate equals the rated air flow rate.

Field: Coil Air Inlet Node Name[LINK]

This alpha field defines the name of the air inlet node entering the DX cooling coil.

Field: Coil Air Outlet Node Name[LINK]

This alpha field defines the name of the air outlet node exiting the DX cooling coil.

Field: Name of Water Storage Tank for Condensate Collection[LINK]

This field is optional. It is used to describe where condensate from the coil is collected. If blank or omitted, then any coil condensate is discarded. Enter the name of Water Storage Tank object defined elsewhere and the condensate will then be collected in that tank.

Following is an example input for a Coil:Cooling:DX:VariableRefrigerantFlow object.

COIL:Cooling:DX:VariableRefrigerantFlow,

TU1 VRF DX Cooling Coil, !- Coil Name

VRFAvailSched, !- Availability Schedule Name

autosize, !- Gross Rated Total Cooling Capacity {W}

autosize, !- Gross Rated Sensible Heat Ratio

autosize, !- Rated Air Flow Rate {m3/s}

VRFTUCoolCapFT, !- Cooling Capacity Ratio Modifier Function of Temperature Curve Name

VRFACCoolCapFFF, !- Cooling Capacity Modifier Curve Function of Flow Fraction Name

TU1 VRF DX CCoil Inlet Node, !- Coil Air Inlet Node

TU1 VRF DX CCoil Outlet Node; !- Coil Air Outlet Node

HVAC,Average, Cooling Coil Total Cooling Rate [W]

HVAC,Sum, Cooling Coil Total Cooling Energy [J]

HVAC,Average, Cooling Coil Sensible Cooling Rate [W]

HVAC,Sum, Cooling Coil Sensible Cooling Energy [J]

HVAC,Average, Cooling Coil Latent Cooling Rate [W]

HVAC,Sum, Cooling Coil Latent Cooling Energy [J]

HVAC,Average, Cooling Coil Runtime Fraction []

Evaporative-cooled condenser:

HVAC,Average,Cooling Coil Condensate Volume Flow Rate [m3/s]

Zone,Meter,Condensate:OnSiteWater [m3]

HVAC,Sum,Cooling Coil Condensate Volume [m3]

Cooling Coil Total Cooling Rate [W][LINK]

This field is the total (sensible and latent) cooling rate output of the DX coil in Watts. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Total Cooling Energy [J][LINK]

This is the total (sensible plus latent) cooling output of the DX coil in Joules over the time step being reported. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil. This output is also added to a meter with Resource Type = EnergyTransfer, End Use Key = CoolingCoils, Group Key = System (Ref. Output:Meter objects).

Cooling Coil Sensible Cooling Rate [W][LINK]

This output is the moist air sensible cooling rate output of the DX coil in Watts. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Sensible Cooling Energy [J][LINK]

This is the moist air sensible cooling output of the DX coil in Joules for the time step being reported. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Latent Cooling Rate [W][LINK]

This is the latent cooling rate output of the DX coil in Watts. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Latent Cooling Energy [J][LINK]

This is the latent cooling output of the DX coil in Joules for the time step being reported. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Runtime Fraction [][LINK]

This is the runtime fraction of the DX coil compressor and condenser fan(s) for the time step being reported.

Cooling Coil Condensate Volume Flow Rate [m3/s][LINK]

Cooling Coil Condensate Volume [m3][LINK]

These outputs are the rate and volume of water collected as condensate from the coil. These reports only appear if a water storage tank is named in the input object.

Coil:Heating:DX:VariableRefrigerantFlow[LINK]

The variable refrigerant flow (VRF) DX heating coil model uses performance information at rated conditions along with performance curves for variations in total capacity, energy input ratio and part load fraction to determine performance at part-load conditions. The impacts of defrost operation is modeled based a combination of user inputs and empirical models taken from the air-to-air heat pump algorithms in DOE-2.1E.

The VRF DX heating coil input requires an availability schedule, the gross rated heating capacity and the rated air volume flow rate. The rated air volume flow rate should be between 0.00008056 m3/s and 0.00002684 m3/s per watt of gross rated heating capacity.

Two performance curves are required. The first performance curve defines the heating capacity as a function of indoor air dry-bulb and outdoor condenser entering air dry-bulb or wet-bulb temperature. The outdoor air temperature type is specified in the variable refrigerant flow air-to-air heat pump object. The second performance curve defines the change in heating capacity as a function of air flow fraction. Each of these performance curves are further discussed here.

- Heating capacity modifier curve (function of temperature, specified in Heat Pump)

The heating capacity modifier curve (function of temperature) can be a function of both the outdoor wet-bulb temperature and indoor air dry-bulb temperature. The curve is normalized to 1 at 21.11 C indoor dry-bulb temperature and if a biquadratic curve is used also at 6.11 C outdoor wet-bulb or 8.33 outdoor dry-bulb temperature. The outdoor air temperature type is specified in the variable refrigerant flow air-to-air heat pump object. Users have the choice of a bi-quadratic curve with two independent variables or a tri-quadratic curve with three independent variable. The tri-quadratic curve is recommended if sufficient manufacturer data is available as it provides sensitivity to the combined total capacity of all indoor units connected to the heat pump condenser and a more realistic output. The output of this curve is multiplied by the gross rated heating capacity to give the gross heating capacity at specific temperature operating conditions (i.e., at an outdoor or indoor air temperature different from the rating point temperature) and the combination ratio of the installed system.

- Heating capacity modifier curve (function of flow fraction, specified in DX coil)

The heating capacity modifier curve (function of flow fraction) is a quadratic or cubic curve with the independent variable being the ratio of the actual air flow rate across the heating coil to the rated air flow rate (i.e., fraction of full load flow). The curve is normalized to have the value of 1.0 when the actual air flow rate equals the rated air flow rate. The output of this curve is multiplied by the gross rated heating capacity and the heating capacity modifier curve (function of temperature) to give the gross heating capacity at the specific temperature and air flow conditions at which the coil is operating.

This alpha field defines a unique user-assigned name for an instance of a VRF DX heating coil. Any reference to this DX heating coil by another object will use this name.

Field: Availability Schedule Name[LINK]

This alpha field defines the name of the schedule (ref: Schedule) that denotes whether the DX heating coil can run during a given time period. A schedule value greater than 0 (usually 1 is used) indicates that the unit can be on during the time period. A value less than or equal to 0 (usually 0 is used) denotes that the unit must be off for the time period. If this field is blank, the schedule has values of 1 for all time periods.

Field: Gross Rated Heating Capacity[LINK]

This numeric field defines the total, full load gross heating capacity in watts of the DX coil unit at rated conditions (outside air dry-bulb temperature of 8.33 C, outside air wet-bulb temperature of 6.11 C, heating coil entering air dry-bulb temperature of 21.11 C, heating coil entering air wet-bulb temperature of 15.55 C, and a heating coil air flow rate defined by field rated air flow volume below). The value entered here must be greater than 0. The gross total heating capacity should not account for the effect of supply air fan heat.

Field: Rated Air Flow Rate[LINK]

This numeric field defines the volume air flow rate, in m3 per second, across the DX heating coil at rated conditions. The value entered here must be greater than 0. The rated air volume flow rate should be between 0.00004027 m3/s and 0.00006041 m3/s per watt of gross rated heating capacity. The gross rated heating capacity and the gross rated COP should be performance information for the unit with outside air dry-bulb temperature of 8.33 C, outside air wet-bulb temperature of 6.11 C, heating coil entering air dry-bulb temperature of 21.11 C, heating coil entering air wet-bulb temperature of 15.55 C, and the rated air volume flow rate defined here.

Field: Coil Air Inlet Node[LINK]

This alpha field defines the name of the HVAC system node from which the DX heating coil draws its inlet air.

Field: Coil Air Outlet Node[LINK]

This alpha field defines the name of the HVAC system node to which the DX heating coil sends its outlet air.

Field: Heating Capacity Ratio Modifier Function of Temperature Curve Name[LINK]

This alpha field defines the heating capacity ratio modifier as a function of indoor dry-bulb temperature or indoor dry-bulb and outdoor wet-bulb temperatures. This curve is a linear, quadratic, or cubic curve if the heating capacity is solely a function of indoor dry-bulb temperature (i.e., the indoor terminal units weighted average inlet air dry-bulb temperatures). Without specific manufacturers data indicating otherwise, the use of a single independent variable is recommended for this coil type. If, however, the user has reason to believe the heating capacity is both a function of indoor dry-bulb temperature and outdoor wet-bulb temperature (and has manufacturers data to create the performance curve), a bi-quadratic equation using weighted average indoor dry-bulb temperature and condenser entering air wet-bulb temperature as the independent variables may be used. See the Engineering Reference for more discussion on using this input field.

Note: The choice of using either outdoor dry-bulb temperature or outdoor wet-bulb temperature as the independent variable in this performance curve is set in the parent object AirConditioner: VariableRefrigerantFlow.

Field: Heating Capacity Ratio Modifier Function of Flow Fraction Curve Name[LINK]

This alpha field defines the name of a linear, quadratic or cubic performance curve (ref: Performance Curves) that parameterizes the variation of heating capacity as a function of the ratio of actual air flow rate across the heating coil to the rated air flow rate (i.e., fraction of full load flow). The output of this curve is multiplied by the gross rated heating capacity and the heating capacity modifier curve (function of temperature) to give the gross heating capacity at the specific temperature and air flow conditions at which the coil is operating. The curve is normalized to have the value of 1.0 when the actual air flow rate equals the rated air flow rate.

Following is an example input for the object.

COIL:Heating:DX:VariableRefrigerantFlow,

TU1 VRF DX Heating Coil, !- Coil Name

VRFAvailSched, !- Availability Schedule

autosize, !- Gross Rated Heating Capacity {W}

autosize, !- Rated Air Flow Rate {m3/s}

TU1 VRF DX CCoil Outlet Node, !- Coil Air Inlet Node

TU1 VRF DX HCoil Outlet Node, !- Coil Air Outlet Node

VRFTUHeatCapFT, !- Heating Capacity Ratio Modifier Function of Temperature Curve Name

VRFACCoolCapFFF; !- Total heating capacity modifier curve Function of Flow Fraction

HVAC,Average, Heating Coil Heating Rate [W]

HVAC,Sum, Heating Coil Heating Energy [J]

HVAC,Average, Heating Coil Runtime Fraction []

Heating Coil Heating Rate [W][LINK]

This field is the total heating rate output of the DX coil in Watts. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil.

Heating Coil Heating Energy [J][LINK]

This is the total heating output of the DX coil in Joules over the time step being reported. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil. This output is also added to a meter with Resource Type = EnergyTransfer, End Use Key = HeatingCoils, Group Key = System (ref. Output:Meter objects).

Heating Coil Runtime Fraction [][LINK]

This is the runtime fraction of the DX coil compressor and condenser fan(s) for the time step being reported.

Coil:Cooling:DX:VariableRefrigerantFlow:FluidTemperatureControl[LINK]

This coil object is specifically designed for the physics based VRF model applicable for Fluid Temperature Control (VRF-FluidTCtrl). It describes the performance of the indoor unit coil of the VRF system operating at cooling mode. The name of this object is entered as an input to the object ZoneHVAC:TerminalUnit:VariableRefrigerantFlow. The outdoor unit part of the VRF system is modeled separately (refer to AirConditioner:VariableRefrigerantFlow:FluidTemperatureControl object).

This alpha field defines a unique user-assigned name for an instance of a VRF DX cooling coil. Any reference to this DX cooling coil by another object will use this name. This cooling coil name must be entered in the AirConditioner:VariableRefrigerantFlow:FluidTemperatureControl object. No other system type uses this specific coil.

Field: Availability Schedule Name[LINK]

This alpha field defines the name of the coil availability schedule. A name should be entered to define the availability of the coil. Schedule values of 0 denote the DX cooling coil is off. A schedule value greater than 0 indicates that the coil can operate during the time period. If this field is blank, the schedule has values of 1 for all time periods.

Field: Coil Air Inlet Node[LINK]

This alpha field defines the name of the air inlet node entering the DX cooling coil.

Field: Coil Air Outlet Node[LINK]

This alpha field defines the name of the air outlet node exiting the DX cooling coil.

Field: Rated Total Cooling Capacity[LINK]

This numeric field defines the gross rated total cooling capacity of the DX cooling coil in watts. The total cooling capacity should be a gross , i.e., the effect of supply air fan heat NOT accounted for. Note that if autosize is selected for this field, the cooling design supply air temperature provided in the Sizing:Zone object needs to be in accordance with the Indoor Unit Evaporating Temperature Function of Superheating Curve provided below in this object.

Field: Rated Sensible Heat Ratio[LINK]

This numeric field defines the gross sensible heat ratio (sensible capacity divided by total cooling capacity) of the DX cooling coil at rated conditions. Both the sensible and total cooling capacities used to define the Rated SHR should be gross (i.e., the effect of supply air fan heat is NOT accounted for)

Field: Indoor Unit Reference Superheating[LINK]

This numeric field defines the reference superheating degrees of the indoor unit. If this field is blank, the default value of 5.0 C is used.

Field: Indoor Unit Evaporating Temperature Function of Superheating Curve Name[LINK]

This alpha field defines the name of a quadratic performance curve that parameterizes the variation of indoor unit evaporating temperature as a function of superheating degrees. The output of this curve is the temperature difference between the coil surface air temperature and the evaporating temperature.

Field: Name of Water Storage Tank for Condensate Collection[LINK]

This field is optional. It is used to describe where condensate from the coil is collected. If blank or omitted, then any coil condensate is discarded. Enter the name of Water Storage Tank object defined elsewhere and the condensate will then be collected in that tank.

Following is an example input for a Coil:Cooling:DX:VariableRefrigerantFlow:FluidTemperatureControl object.

Coil:Cooling:DX:VariableRefrigerantFlow:FluidTemperatureControl,

TU1 VRF DX Cooling Coil, !- Name

VRFAvailSched, !- Availability Schedule Name

TU1 VRF DX CCoil Inlet Node, !- Coil Air Inlet Node

TU1 VRF DX CCoil Outlet Node, !- Coil Air Outlet Node

autosize, !- Rated Total Cooling Capacity {W}

autosize, !- Rated Sensible Heat Ratio

3, !- Indoor Unit Reference Superheating Degrees {C}

IUEvapTempCurve, !- Indoor Unit Evaporating Temperature Function of Superheating Curve Name

; !- Name of Water Storage Tank for Condensate Collection

Curve:Quadratic,

IUEvapTempCurve, !- Name

0, !- Coefficient1 Constant

0.843, !- Coefficient2 x

0, !- Coefficient3 x**2

0, !- Minimum Value of x

15, !- Maximum Value of x

, !- Minimum Curve Output

, !- Maximum Curve Output

Temperature, !- Input Unit Type for X

Temperature; !- Output Unit Type

HVAC,Average, Cooling Coil Total Cooling Rate [W]

HVAC,Sum, Cooling Coil Total Cooling Energy [J]

HVAC,Average, Cooling Coil Sensible Cooling Rate [W]

HVAC,Sum, Cooling Coil Sensible Cooling Energy [J]

HVAC,Average, Cooling Coil Latent Cooling Rate [W]

HVAC,Sum, Cooling Coil Latent Cooling Energy [J]

HVAC,Average, Cooling Coil Runtime Fraction []

HVAC,Average, Cooling Coil VRF Evaporating Temperature [C]

HVAC,Average, Cooling Coil VRF Super Heating Degrees [C]

Evaporative-cooled condenser:

HVAC,Average,Cooling Coil Condensate Volume Flow Rate [m3/s]

Zone,Meter,Condensate:OnSiteWater [m3]

HVAC,Sum,Cooling Coil Condensate Volume [m3]

Cooling Coil Total Cooling Rate [W][LINK]

This field is the total (sensible and latent) cooling rate output of the DX coil in Watts. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Total Cooling Energy [J][LINK]

This is the total (sensible plus latent) cooling output of the DX coil in Joules over the time step being reported. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil. This output is also added to a meter with Resource Type = EnergyTransfer, End Use Key = CoolingCoils, Group Key = System (Ref. Output:Meter objects).

Cooling Coil Sensible Cooling Rate [W][LINK]

This output is the moist air sensible cooling rate output of the DX coil in Watts. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Sensible Cooling Energy [J][LINK]

This is the moist air sensible cooling output of the DX coil in Joules for the time step being reported. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Latent Cooling Rate [W][LINK]

This is the latent cooling rate output of the DX coil in Watts. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Latent Cooling Energy [J][LINK]

This is the latent cooling output of the DX coil in Joules for the time step being reported. This is determined by the inlet and outlet air conditions and the air mass flow rate through the coil.

Cooling Coil Runtime Fraction [][LINK]

This is the runtime fraction of the DX coil compressor and condenser fan(s) for the time step being reported.

Cooling Coil VRF Evaporating Temperature [C][LINK]

This is the evaporating temperature of the VRF system operating at cooling mode. This value is manipulated by the VRF system considering the load conditions of all the zones it serves. It affects the cooling coil surface temperature and thus the cooling capacity of the coil.

Cooling Coil VRF Super Heating Degrees [C][LINK]

This is the super heating degrees of the VRF system operating at cooling mode. This value is manipulated by each VRF terminal unit to adjust the cooling capacity of the coil considering the load conditions of the zone. It affects the cooling coil surface temperature and thus the cooling capacity of the coil.

Cooling Coil Condensate Volume Flow Rate [m3/s][LINK]

This is the volumetric rate of water collected as condensate from the coil. This report only appears if a water storage tank is named in the input object.

Cooling Coil Condensate Volume [m3][LINK]

This is the volume of water collected as condensate from the coil. This report only appears if a water storage tank is named in the input object.

Coil:Heating:DX:VariableRefrigerantFlow:FluidTemperatureControl[LINK]

This coil object is specifically designed for the physics based VRF model applicable for Fluid Temperature Control (VRF-FluidTCtrl). It describes the performance of the indoor unit coil of the VRF system operating at heating mode. The name of this object is entered as an input to the object ZoneHVAC:TerminalUnit:VariableRefrigerantFlow. The outdoor unit part of the VRF system is modeled separately (refer to AirConditioner:VariableRefrigerantFlow:FluidTemperatureControl object).

This alpha field defines a unique user-assigned name for an instance of a VRF DX heating coil. Any reference to this DX heating coil by another object will use this name. This heating coil name must be entered in the AirConditioner:VariableRefrigerantFlow:FluidTemperatureControl object. No other system type uses this specific coil.

Field: Availability Schedule[LINK]

This alpha field defines the name of the schedule (ref: Schedule) that denotes whether the DX heating coil can run during a given time period. A schedule value greater than 0 (usually 1 is used) indicates that the unit can be on during the time period. A value less than or equal to 0 (usually 0 is used) denotes that the unit must be off for the time period. If this field is blank the unit is always available.

Field: Coil Air Inlet Node[LINK]

This alpha field defines the name of the HVAC system node from which the DX heating coil draws its inlet air.

Field: Coil Air Outlet Node[LINK]

This alpha field defines the name of the HVAC system node to which the DX heating coil sends its outlet air.

Field: Rated Total Heating Capacity[LINK]

This numeric field defines the total, full load gross heating capacity in watts of the DX coil unit at rated conditions. The value entered here must be greater than 0. The gross total heating capacity should not account for the effect of supply air fan heat.

Field: Indoor Unit Reference Subcooling[LINK]

This numeric field defines the reference subcooling degrees of the indoor unit. If this field is blank, the default value of 5.0 C is used.

Field: Indoor Unit Condensing Temperature Function of Subcooling Curve Name[LINK]

This alpha field defines the name of a quadratic performance curve that parameterizes the variation of indoor unit condensing temperature as a function of subcooling degrees. The output of this curve is the temperature difference between the condensing temperature and the coil surface air temperature.

Following is an example input for a Coil:Heating:DX:VariableRefrigerantFlow:FluidTemperatureControl object.

Coil:Heating:DX:VariableRefrigerantFlow:FluidTemperatureControl,

TU1 VRF DX Heating Coil, !- Name

VRFAvailSched, !- Availability Schedule

TU1 VRF DX CCoil Outlet Node, !- Coil Air Inlet Node

TU1 VRF DX HCoil Outlet Node, !- Coil Air Outlet Node

autosize, !- Rated Total Heating Capacity {W}

5, !- Indoor Unit Reference Subcooling Degrees {C}

IUCondTempCurve; !- Indoor Unit Condensing Temperature Function of Subcooling Curve Name

Curve:Quadratic,

IUCondTempCurve, !- Name

-1.85, !- Coefficient1 Constant

0.411, !- Coefficient2 x

0.0196, !- Coefficient3 x**2

0, !- Minimum Value of x

20, !- Maximum Value of x

, !- Minimum Curve Output

, !- Maximum Curve Output

Temperature, !- Input Unit Type for X

Temperature; !- Output Unit Type

HVAC,Average, Heating Coil Heating Rate [W]

HVAC,Sum, Heating Coil Heating Energy [J]

HVAC,Average, Heating Coil Runtime Fraction []

Heating Coil VRF Condensing Temperature [C]

Heating Coil VRF Subcooling Degrees [C]

Heating Coil Heating Rate [W][LINK]

This field is the total heating rate output of the DX coil in Watts. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil.

Heating Coil Heating Energy [J][LINK]

This is the total heating output of the DX coil in Joules over the time step being reported. This is determined by the coil inlet and outlet air conditions and the air mass flow rate through the coil. This output is also added to a meter with Resource Type = EnergyTransfer, End Use Key = HeatingCoils, Group Key = System (ref. Output:Meter objects).

Heating Coil Runtime Fraction [][LINK]

This is the runtime fraction of the DX coil compressor and condenser fan(s) for the time step being reported.

Cooling Coil VRF Condensing Temperature [C][LINK]

This is the condensing temperature of the VRF system operating at heating mode. This value is manipulated by the VRF system considering the load conditions of all the zones it serves. It affects the heating coil surface temperature and thus the heating capacity of the coil.

Cooling Coil VRF Subcooling Degrees [C][LINK]

This is the subcooling degrees of the VRF system operating at heating mode. This value is manipulated by each VRF terminal unit to adjust the heating capacity of the coil considering the load conditions of the zone. It affects the heating coil surface temperature and thus the heating capacity of the coil.

Coil:Heating:Fuel[LINK]

The fuel heating coil is a simple capacity model with a user inputted gas burner efficiency. The default for the burner efficiency is 80%. This coil will be simpler than shown in Figure [fig:example-air-loop-heating-cooling-coil] since it will only have air nodes to connect it in the system. The coil can be used in the air loop simulation or in the zone equipment as a reheat coil. Depending on where it is used determines if this coil is temperature or capacity controlled. If used in the air loop simulation it will be controlled to a specified temperature scheduled from the Setpoint Manager. If it is used in zone equipment, it will be controlled from the zone thermostat by meeting the zone demand.

A unique identifying name for each coil.

Field: Availability Schedule Name[LINK]

Schedule that defines when the coil is available. If the schedule s value is 0.0, then the coil is not available and flow will not be requested. If the schedule s value is > 0.0 (usually 1 is used), the coil is available. If this field is blank, the schedule has values of 1 for all time periods. Schedule values must be > = 0 and < = 1.

Field: Fuel Type[LINK]

This field designates the appropriate fuel type for the coil. Valid fuel types are: Gas, NaturalGas, Propane, FuelOil#1, FuelOil#2, Diesel, Gasoline, Coal, Steam, DistrictHeating, DistrictCooling, OtherFuel1 and OtherFuel2. The fuel type triggers the application of consumption amounts to the appropriate energy meters. NaturalGas is the default.

Field: Burner Efficiency[LINK]

This is user inputted gas burner efficiency (decimal, not percent) and is defaulted to 80%.

Field: Nominal Capacity[LINK]

This is the maximum capacity of the coil (W). This controlled coil will only provide the needed capacity to meet the control criteria whether it is temperature or capacity controlled. This field is autosizable.

Field: Air Inlet Node Name[LINK]

The name of the air inlet to the coil, i.e. Heating Coil Air Inlet Node.

Field: Air Outlet Node Name[LINK]

The name of the air outlet from the coil, i.e. Heating Coil Air Outlet Node.

Field: Temperature Setpoint Node Name[LINK]

If the coil is used in the air loop simulation and is temperature controlled using a Set Point Manager, then the node that is the control node needs to be specified here. If the coil is used in an air terminal unit, the coil is load controlled and a control node set point is not required.

Field: Parasitic Electric Load[LINK]

This is the parasitic electric load associated with the coil operation, such as an inducer fan, etc.. This will be modified by the PLR (or coil runtime fraction if a part-load fraction correlation is provided in the next input field) to reflect the time of operation in a simulation timestep.

Field: Part Load Fraction Correlation Curve Name[LINK]

This alpha field defines the name of a quadratic or cubic performance curve (Ref: Performance Curves) that parameterizes the variation of fuel consumption rate by the heating coil as a function of the part load ratio (PLR, sensible heating load/nominal capacity of the heating coil). For any simulation timestep, the nominal fuel consumption rate (heating load/burner efficiency) is divided by the part-load fraction (PLF) if a part-load curve has been defined. The part-load curve accounts for efficiency losses due to transient coil operation.

The part-load fraction correlation should be normalized to a value of 1.0 when the part load ratio equals 1.0 (i.e., no efficiency losses when the heating coil runs continuously for the simulation timestep). For PLR values between 0 and 1 ( 0 < = PLR < 1), the following rules apply:

PLF > = 0.7 and PLF > = PLR

If PLF < 0.7 a warning message is issued, the program resets the PLF value to 0.7, and the simulation proceeds. The runtime fraction of the heating coil is defined a PLR/PLF. If PLF < PLR, then a warning message is issues and the runtime fraction of the coil is limited to 1.0.

A typical part load fraction correlation for a conventional gas heating coil (e.g., residential furnace) would be:

PLF = 0.8 + 0.2(PLR)

Field: Parasitic Fuel Load[LINK]

This numeric field is the parasitic fuel load associated with the coil’s operation (Watts), such as a standing pilot light. The model assumes that this parasitic load is consumed only for the portion of the simulation timestep where the heating coil is not operating.

HVAC,Sum,Heating Coil Heating Energy [J]

HVAC,Average,Heating Coil Heating Rate [W]

HVAC,Sum,Heating Coil Gas Energy [J]

HVAC,Average,Heating Coil <Fuel Type> Rate [W]

HVAC,Sum,Heating Coil Electric Energy [J]

HVAC,Average,Heating Coil Electric Power [W]

HVAC,Average,Heating Coil Runtime Fraction []

HVAC,Sum,Heating Coil Ancillary <Fuel Type> Energy [J]

HVAC,Average,Heating Coil Ancillary <Fuel Type> Rate [W]

Heating Coil Heating Energy [J][LINK]

This field is the total heating output of the coil to the air in Joules over the timestep being reported. This output is also added to a meter with Resource Type = EnergyTransfer, End Use Key = HeatingCoils, Group Key = System (ref. Output:Meter objects).

Heating Coil Heating Rate [W][LINK]

This field is the average heating rate output of the coil to the air in Watts over the timestep being reported.

Heating Coil <Fuel Type> Energy [J][LINK]

This field is the fuel consumption of the heating coil in Joules over the timestep being reported, including the impacts of part-load performance if a part load fraction correlation is specified. This output is also added to a meter with Resource Type = Gas, End Use Key = Heating, Group Key = System (ref. Output:Meter objects).

Heating Coil <Fuel Type> Rate [W][LINK]

This field is the average gas consumption rate of the coil in Watts over the timestep being reported, including the impacts of part-load performance if a part load fraction correlation is specified.

Heating Coil Electric Energy [J][LINK]

This field is the electric consumption of the heating coil auxiliaries in Joules over the timestep being reported (e.g., inducer fan). This output is also added to a meter with Resource Type = Electricity, End Use Key = Heating, Group Key = System (ref. Output:Meter objects).

Heating Coil Electric Power [W][LINK]

This field is the average electric consumption rate of the heating coil auxiliaries (e.g., inducer fan) in Watts over the timestep being reported.

Heating Coil Runtime Fraction [][LINK]

This field is the runtime fraction of the coil over the timestep being reported.

Heating Coil Ancillary <Fuel Type> Energy [J][LINK]

This field is the parasitic fuel consumption of the heating coil in Joules over the timestep being reported (e.g., standing pilot light). The model assumes that the parasitic load is accumulated only for the portion of the simulation timestep where the gas heating coil is not operating. This output is also added to a meter with Resource Type = ‘<Fuel Type>’, End Use Key = Heating, Group Key = System (ref. Output:Meter objects).

Heating Coil Ancillary <Fuel Type> Rate [W][LINK]

This field is the average parasitic gas consumption rate of the heating coil (e.g., standing pilot light) in Watts over the timestep being reported. The model assumes that the parasitic load is present only for the portion of the simulation timestep where the heating coil is not operating.

Coil:Heating:Gas:MultiStage[LINK]

The multi stage gas heating coil is a simple capacity model with a user inputted gas burner efficiencies at different stages. This coil will only have air nodes to connect it in the system. The coil can be used in the air loop simulation or in the zone equipment as a reheat coil. Depending on where it is used determines if this coil is temperature or capacity controlled. If used in the air loop simulation it will be controlled to a specified temperature scheduled from the Setpoint Manager. If it is used in zone equipment, it will be controlled from the zone thermostat by meeting the zone demand. For the time being, this coil model can only be called by the parent object AirLoopHVAC:UnitaryHeatPump:AirToAir:MultiSpeed.

A unique identifying name for each coil.

Field: Availability Schedule Name[LINK]

Schedule that defines when the coil is available. If the schedule s value is 0.0, then the coil is not available and flow will not be requested. If the schedule s value is > 0.0 (usually 1 is used), the coil is available. If this field is blank, the schedule has values of 1 for all time periods. Schedule values must be > = 0 and < = 1.

Field: Air Inlet Node Name[LINK]

The name of the air inlet to the gas coil, i.e. Heating Coil Air Inlet Node.

Field: Air Outlet Node Name[LINK]