Chilled-Water-Based Air Cooling Coil[LINK]

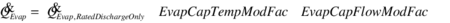

The input object Coil:Cooling:Water is simpler than the detailed geometry model. The simple model provides a good prediction of the air and water outlet conditions without requiring the detailed geometric input required for the detailed model. A greatly simplified schematic of enthalpy and temperature conditions in a counter flow cooling/dehumidifying coil is shown in the schematic Figure 161. The input required to model the coil includes only a set of thermodynamic design inputs, which require no specific manufacturer’s data. The coil simulation model is essentially a modification of one presented by Elmahdy and Mitalas (1977), TRNSYS, 1990 and Threlkeld, J.L. 1970. The model calculates the UA values required for a Dry, Wet and Part Wet & Part Dry Coil and iterates between the Dry and Wet Coil to output the fraction wet. There are two modes of flow operation for this model: Cross Flow, which is widely applicable in HVAC systems and the second being Counter flow mode. The default value in program is set up for Counter Flow. In addition the coil has two modes of analysis: Simple Analysis and Detailed Analysis. The Simple analysis mode operates the coil as either wet or dry while the detailed mode simulates the coil as part wet part-dry. While the detailed mode provides more accurate results, it is significantly slower than the simple model. The simple mode gives good results for an annual simulation but will not be adequate for a time step performance analysis.

Heat Transfer and Energy Balance[LINK]

The cooling coil may be completely dry, completely wet with condensation, or it may have wet and dry sections. The actual condition of the coil surface depends on the humidity and temperature of the air passing over the coil and the coil surface temperature. The part-dry part-wet case represents the most general scenario for the coil surface conditions. There are subroutines present in the model for both the dry and wet regions of the coil, and a subroutine that iterates between the dry and wet subroutines to calculate the fraction of the coil surface that is wet. For each region the heat transfer rate from air to water may be defined by the rate of enthalpy change in the air and in the water. The rates must balance between each medium for energy to be conserved.

Model Description[LINK]

The Model has two blocks: 1st = Design Block with the Design Inputs. This block calculates the Design U-Factor Times Area Value (UA) values required by the model. Using these UA values the model simulates the operating conditions. The operating block is the one containing the operating conditions, the conditions at which the coil operates. Following is the list of Design and Operating inputs and subsequently the Design and Operating variables used in the model.

Design Inputs (User Inputs)

| DesWaterVolFlowRate: |

Maximum Water Volume Flow Rate |

| DesAirVolFlowRate: |

Maximum Air Volume Flow Rate |

| DesInletWaterTemp: |

Inlet Water Temperature at Design Condition |

| DesInletAirTemp: |

Inlet Air Temperature at Design Condition |

| DesOutletAirTemp: |

Outlet Air Temperature at Design Condition |

| DesInletAirHumRat: |

Inlet Air Humidity Ratio at Design Conditions |

| DesOutletAirHumRat: |

Outlet Air Humidity Ratio at Design Conditions. |

Operating Conditions (From Nodes – not user inputs)

|

InletWaterMassFlowRate:

|

Entering Water Mass Flow Rate at operating condition

|

|

InletWaterTemp:

|

Inlet Water Temperature at operating condition

|

|

InletAirMassFlowRate:

|

Entering Air Mass Flow Rate at operating condition

|

|

InletAirTemp:

|

Inlet Air Temperature at operating condition

|

|

InletAirHumRat:

|

Entering air humidity ratio at operating conditions

|

: Operating Conditions (From Nodes – not user inputs)

The various U-Factor Times Area values (UA) required by this model are calculated from the above inputs, which are explained later in the document. The various UA are:

UA Descriptions of Model

|

CoilUATotal:

|

Overall heat transfer coefficient (W/C)

|

|

CoilUAInternal:

|

Overall internal UA (W/C)

|

|

CoilUAExternal:

|

Overall external UA (W/C)

|

|

CoilUInternal:

|

Internal overall heat transfer coefficient (W/m2∙C)

|

|

CoilUWetExternal:

|

Wet part external overall heat transfer coefficient (W/m2∙C)

|

|

CoilUDryExternal:

|

Dry part external overall heat transfer coefficient (W/m2∙C)

|

: UA Descriptions of Model

The UA values are calculated assuming a wet coil at the design conditions. Following are a few important calculations to understand the working of the model. The model is basically divided into two blocks: the Design Block and the Operating Block.

The Design Block is a one time calculation. The aim of the Design Block is to calculate the Coil UA for use in the operating Block.

The above calculations yield coil UA’s for the design inlet conditions and air and water flow rates. As the flow rates vary during the time step calculations, the UA’s need to be adjusted, since coil UA’s are a rather strong function of air and water side flow rates. Each time step the coil UA’s are modified using the same formulas as are used in the hot water coil model. Refer to that model for the flow dependences.

Operating Block Calculations:[LINK]

There are two modes of coil analysis in the operating block. They are the Simple analysis mode and the detailed analysis mode. The simple analysis mode assumes the coil to be either all wet or either all dry and execute the model , on the other hand the detailed mode checks for part wet part dry mode of operation and reports surface area wet fraction of coil, however the program execution time in detailed mode is noticeably higher.

The operating block for Detailed Mode Analysis of this coil model is divided into three modes of coil performance. The modes being

- Coil is completely dry: There is no moisture condensation on the coil surface and the coil is a dry coil. This is an extreme condition when the entering air has very low humidity ratio or is dry air.

- Coil is completely wet: The entire coil is wet due to complete condensation on the surface of the coil.

- Part Wet Part Dry Mode: This is the usual/frequent mode of operation of coil, as shown in figure 1, where part of the coil at entry of air is dry and as air cools condensation occurs and part of the coil becomes wet.

The Part Wet Part Dry Mode of operation is essentially a function the Coil Completely Dry and Coil Completely Wet mode. This subroutine iterates between the Dry Coil and the Wet Coil to give outputs, a detailed explanation is given later in the document. The operating block requires 5 inputs, which are mentioned earlier in the document. These inputs are automatically generated from the node connections in Energy Plus. The user does not have to input any information to run this coil model.

The option to identify which mode of operation the coil should perform ie, for a given set of inputs would the coil be Dry, Wet or Part Wet Part Dry, is decided by set of conditions described below.

-

IF (Temperature Dewpoint Air < Water Inlet Temperature) THEN the coil is Dry and we call the Subroutine Coil Completely Dry. In this case outlet temperature of air would be higher than the air dewpoint and hence there would be no condensation.

-

IF (Temperature Dewpoint Air > Water Inlet Temperature) THEN the coil is completely wet, call subroutine Coil Completely Wet, it is assumed that moisture condensation occurs over completely surface of the coil. However we go ahead and check for the coil being partially wet with the following condition.

-

IF (AirDewPointTemp < AirInletCoilSurfTemp) THEN, the coil is Partially Wet because there is possibility that air temperature will go below its dewpoint and moisture will condense on latter part of the cooling coil.

The Operating Block for Simple Mode Analysis is divided into two modes of coil performance, the two modes being

- Coil is completely dry: There is no moisture condensation on the coil surface and the coil is a dry coil.

- Coil is completely wet: The entire coil is wet due to complete condensation on the surface of the coil.

The option to identify which mode of operation the Simple mode analysis should perform ie, for a given set of inputs would the coil be Dry or Wet is decided by set of conditions described below.

-

IF (Temperature Dewpoint Air < Water Inlet Temperature) THEN the coil is Dry and we call the Subroutine Coil Completely Dry. In this case outlet temperature of air would be higher than the air dewpoint and hence there would be no condensation.

-

IF (Temperature Dewpoint Air > Water Inlet Temperature) THEN the coil is completely wet, call subroutine Coil Completely Wet, it is assumed that moisture condensation occurs over completely surface of the coil. However we go ahead and check for the coil being partially wet with the following condition.

The above is a simple mode of analysis and the results are very slightly different from the detailed mode of analysis. The algorithms used in Simple mode and the Detailed mode are identically similar. The surface area wet fraction in the coil is reported as 1.0 or 0.0 for wet or dry coil respectively. The program defaults to simple mode of analysis for enabling higher execution speed.

Effectiveness Equations:[LINK]

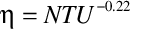

There are two modes of flow for the coil, Counter Flow mode or the Cross Flow mode, default set up is as cross flow since most air condition applications have cross flow heat exchangers. According to the mode of flow the following NTU - Effectiveness relationships are used to calculate coil effectiveness, which is used later by all the three modes (Dry, Wet, Part Wet) for calculating air outlet conditions and heat transfer.

Following are the relations used for calculating effectiveness equation for the Heat exchangers.

Counter Flow Heat Exchanger: Effectiveness Equation:

In Equation the variable Ratio_StreamCapacity is defined as below

In equation capacity of stream is defined as below in equation

NTU in equation , is defined as the Number of Transfer Units, it is a function of Coil UA and the Minimum Capacity of Stream. The Coil UA is a variable in this equation and depends on which mode of the coil operation (Dry, Wet, Part Wet) is calling upon equation , i.e., if it is Coil Completely Dry calling upon the effectiveness equation with the value of Dry UA total, which in our case is defined as CoilUA_total. Equation gives definition for NTU.

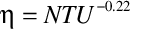

Cross Flow Heat Exchanger: Effectiveness Equation:

The variables in the above equation have already been defined earlier. Depending on the mode of operation of the coil model the cross or the counter flow equations are used to calculate the effectiveness.

Coil Outlet Conditions:[LINK]

Calculating the Outlet Stream Conditions using the effectiveness value from equation or depending on the mode of flow. The energy difference between the outlet and inlet stream conditions gives the amount of heat transfer that has actually take place. Temperature of air and water at outlet to the coil is given as in following equations

In the above equations and the maximum heat transfer is calculated as shown in the following equation

Coil Completely Dry Calculations: (operating block)[LINK]

Since the coil is dry, the sensible load is equal to total load and the same with the humidity ratios at inlet and outlet, as in equations and .

Total Heat Transfer in dry coil is as follows:

The variables in the above equation are calculated earlier in equations and to give the total cooling load on the coil.

Coil Completely Wet Calculations: (operating block)[LINK]

In wet coil we need to account for latent heat transfer, hence calculations are done using enthalpy of air and water instead of stream temperatures Hence we need to define coil UA for the wet coil based on enthalpy of the operating streams and not design streams.

Similar to equations and we calculate the air outlet enthalpy and water outlet enthalpy ie by replacing temperature with enthalpy of the respective streams. The input variable for Coil UA in equation for calculating NTU, in this case it would be enthalpy based and is given as shown in equation

Total Coil Load in case of Wet Coil is the product of mass flow rate of air and enthalpy difference between the inlet and outlet streams as given in the following equation

Once the enthalpy is known the outlet temperatures and outlet humidity ratios of the wet coil are calculated as in equations below.

IF (TempCondensation < PsyTdpFnWPb(InletAirHumRat ,Patm)) THEN

and

OutletAirHumdityRatio = PsyWFnTdbH(OutletAirTemp,EnthAirOutlet)

ELSE

There is no condensation and hence the inlet and outlet Hum Ratios are equal , and outlet temperature is a function of outlet air enthalpy as below

OutletAirTemp = PsyTdbFnHW (EnthalpyAirOutlet, OutletAirHumRat)

and

OutletAirHumRat = InletAirHumRat

ENDIF

Effectiveness η used in equation is defined in equation and Condensation Temperature is calculated using psychrometric function as in equation .

Once the air outlet temperature are known, then sensible load is calculated as a product of capacitance of air and temperature difference at inlet and outlet, as in equation

Coil Part Wet Part Dry Calculations: (operating block)[LINK]

The Coil would perform under part wet part dry conditions when Air Dewpoint Temperature is less than Coil surface temperature at inlet to air. In this case part of the coil used value of Dry UA for heat transfer and part the coil used Wet UA value for heat transfer.

This problem is solved utilizing the fact that the Exit conditions from the Dry Part of the Coil would become the inlet conditions to the wet part of the coil (see Figure 161) and the coil model determines by iteration what fraction of the coil is wet and based on that it calculates the areas and subsequently the UA values of that dry and wet part, based on the area of the dry and wet part respectively. Explained below are the steps followed to the estimating the wet dry behavior of the coil.

- Iterate between the Dry Coil and the Wet Coil. First calculate Coil Completely Dry performance by estimating the wet dry interface water temperature using equation and inputting this variable as the water inlet temperature to dry Coil.

The value of Surface Area Wet fraction is estimated initially as follows

For the above mentioned iteration the value of Coil UA for Wet and Dry part need to be varied according to the new respective area of the wet and dry parts. This estimate of Wet and Dry area is a product of the estimated Surface Area Fraction and total coil external area, which keeps varying as will be explained further in the document.

UA value for Dry part of the Coil is estimated as below.

Where Surface Area Dry =(Total Coil Area – Wet Part Area), where the Wet part area is the product of Surface fraction Wet and Total Coil Area.

UA value for the Wet part of the Coil requires Wet UA external and Wet UA Internal, which are calculated as below.

It is essential to remember that the mode of calculation for the coils remains the same as in completely wet and completely dry mode, only the UA values and water, air outlet and inlet values change.

Now Iterate between the Dry Coil and wet Coil with the above respective UA, and usual operating inputs except the variable water inlet temperature for dry Coil is replaced with Wet Dry Interface Water temperature, and in the Wet Coil the Outlet Air Temperature from dry Coil is the inlet air temperature to Wet Coil. The iteration proceeds till the Outlet Water Temperature from Wet Coil equals the Wet Dry Interface Water Temp, which is the input to Dry Coil.

Dry Part Inputs: (changed operating inputs) :Iteration Case 1: Explained In Programming Fashion:

CALL CoilCompletelyDry (WetDryInterfcWaterTemp, InletAirTemp, DryCoilUA,&

OutletWaterTemp, WetDryInterfcAirTemp, WetDryInterfcHumRat,&

DryCoilHeatTranfer).

Input the calculated values calculated by Dry Coil above into Wet Coil below. The variables have been highlighted in color red and blue.

CALLCoilCompletelyWet (InletWaterTemp, WetDryInterfcAirTemp, WetDryInterfcHumRat

WetPartUAInternal,WetPartUAExternal,&

EstimateWetDryInterfcWaterTemp, OutletAirTemp, OutletAirHumRat,&

WetCoilTotalHeatTransfer, WetCoilSensibleHeatTransfer,&

EstimateSurfAreaWetFraction, WetDryInterfcSurfTemp)

Iterate Between the above two Wet and Dry Coil calls until the two variables in blue ie WetDryInterfcWaterTemp = EstimateWetDryInterfcWaterTemp. The key is to have the difference between the variables (WetDryInterfcWaterTemp – OutletWaterTemp) in Dry Coil equal to (InletWaterTemp-EstimatedWetDryInterfcWaterTemp) in Wet Coil. This equality quantized the relative part of coil that is dry and part that is wet on the basis of heat transfer that has occurred.

After the above convergence check for the coil being dry otherwise iterate to calculate surface fraction area wet.

IF

THEN CoilCompletelyDry

If equation is satisfied then Coil is Dry and simply output the value for Dry Coil calculated else the coil is partially wet and then iterate to find the surface fraction area wet. Start with the initially guess value of surface area fraction (equation wet and iterate on the entire loop starting from until the Wet Dry Interface Temperature equals the Air Dewpoint Temperature. The value of Surface Area fraction wet at which the interface air temperature equals is dewpoint is the transition point from wet to dry and gives the % of coil that is dry and % that is wet.

Graphs Showing the Performance of the coil model at optimum operating conditions are shown below. All values of variable used have been normalized.

IBPSA BuildSim-2004. 2004. Colarado Boulder: An Improvement of Ashrae Secondary HVAC toolkit Simple Cooling Coil Model for Building Simulation, Rahul J Chillar, Richard J Liesen M&IE ,UIUC.

Stoecker, W.F. Design of Thermal Systems,: ME 423 Class Notes , M& IE Dept UIUC.

Brandemeuhl, M. J. 1993. HVAC2 Toolkit: Algorithms and Subroutines for Secondary HVAC Systems Energy Calculations, ASHRAE.

Elmahdy, A.H. and Mitalas, G.P. 1977. “A Simple Model for Cooling and Dehumidifying Coils for Use In Calculating Energy Requirements for Buildings ASHRAE Transactions, Vol.83 Part 2, pp. 103-117.

Threlkeld, J.L. 1970. Thermal Environmental Engineering, 2nd Edition, Englewood Cliffs: Prentice-Hall,Inc. pp. 254-270.

ASHRAE Secondary HVAC Toolkit TRNSYS. 1990. A Transient System Simulation Program: Reference Manual. Solar Energy Laboratory, Univ. Wisconsin-Madison, pp. 4.6.8-1 - 4.6.8-12.

Kays, W.M. and A.L. London. 1964. Compact Heat Exchangers, 2nd Edition, New York: McGraw-Hill.

Clark, D.R.. 1985. HVACSIM+ Building Systems and Equipment Simulation Program Reference Manual, Pub. No. NBSIR 84-2996, National Bureau of Standards, U.S. Department of Commerce, January, 1985

Elmahdy, A.H. 1975. Analytical and Experimental Multi-Row Finned-Tube Heat Exchanger Performance During Cooling and Dehumidifying Processes, Ph.D. Thesis, Carleton University, Ottawa, Canada, December, 1975.

Elmahdy, A.H., and Mitalas, G.P. 1977. “A Simple Model for Cooling and Dehumidifying Coils for Use in Calculating Energy Requirements for Buildings,” ASHRAE Transactions, Vol. 83, Part 2, pp. 103-117.

Chilled-Water-Based Detailed Geometry Air Cooling Coil[LINK]

The input object Coil:Cooling:Water:DetailedGeometry provides a coil model that predicts changes in air and water flow variables across the coil based on the coil geometry. A greatly simplified schematic of enthalpy and temperature conditions in a counterflow cooling/dehumidifying coil is shown in the following schematic figure. In addition, the variables required to model a cooling/dehumidifying coils and their definitions are extensively listed in “Table 53. Coil Geometry and Flow Variables for Coils”. The input required to model the coil includes a complete geometric description that, in most cases, should be derivable from specific manufacturer’s data. The coil simulation model is essentially the one presented by Elmahdy and Mitalas (1977) and implemented in HVACSIM+ (Clark 1985), a modular program also designed for energy analysis of building systems. The model solves the equations for the dry and wet sections of the coil using log mean temperature and log mean enthalpy differences between the liquid and the air streams. Elmahdy and Mitalas state that crossflow counterflow coils with at four rows or more are approximated well by this model. This does not constitute a major limitation since cooling and dehumidifying coils typically have more than four rows.

Heat Transfer and Energy Balance[LINK]

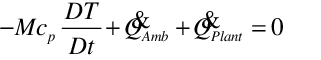

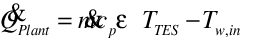

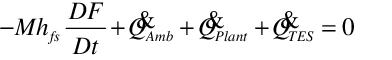

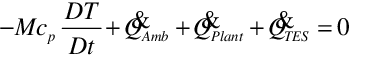

The cooling coil may be completely dry, completely wet with condensation, or it may have wet and dry sections. The actual condition of the coil surface depends on the humidity and temperature of the air passing over the coil and the coil surface temperature. The partly wet-partly dry case represents the most general scenario for the coil surface conditions. The all dry and all wet cases can be considered as limiting solutions of the wet or dry areas respectively going to zero. In the general case, equations are written for both the dry and wet regions of the coil. For each region the heat transfer rate from air to water may be defined by the rate of enthalpy change in the air and in the water. The rates must balance between each medium for energy to be conserved. Equations through express the energy balance between the water and the air for the case of dry and wet coils respectively. Equations and represent the heat transfer rate between water and air based on the actual performance of the coil. The UA parameter can be calculated from the parameters in the following table.

Coil Geometry and Flow Variables for Coils

A

area

LMHD

log mean enthalpy difference

A

air, air side

LMTD

log mean temperature difference

aa, bb

coeff. in enthalpy approximation

mass flow rate

C1, C2

coeff. in air side film coeff.

mf

metal and fouling

Cp

specific heat

viscosity

D

diameter, effective diameter

o

outside (air side)

Dhdr

hydraulic diameter on air side

Pr

Prandtl number

D

dry region

heat transfer rate

thickness

R

overall thermal resistance

spacing

Re

Reynolds number

F

heat transfer film coefficient

ratio of diameters

Fai

variable in fin eff. calculation

s

surface, outside of metal

fin, fins

air side fin geometry

St

Stanton number

H

enthalpy

T

temperature

efficiency

tube

water tube

I0()

mod Bessel fn, 1st kind, ord 0

UAdry

dry heat xfer coeff. * dry area

I1()

mod Bessel fn, 1st kind, ord 1

UcAw

wet heat xfer coeff. * wet area

K0()

mod Bessel fn, 2nd kind, ord 0

ub, ue

variables in fin eff. calculation

K1()

mod Bessel fn, 2nd kind, ord 1

V

average velocity

I

inside (water side)

w

water, water side, or wet region

K1

variable in sol’n form of eq.

wa

humidity ratio

K

thermal conductivity

Z

variables in sol’n form of eq.

L

length

1, 2, 3

positions (see diagram)

Equations through represent two sets of three equations with 7 unknowns:  , Ta,1, Ta,2, Tw,2, Tw,3,

, Ta,1, Ta,2, Tw,2, Tw,3,  ,

,  . However, normally at least four of these variables are specified, for example: inlet water temperature, outlet air temperature, water flow rate, air flow rate, so that the system of equations is effectively closed.

. However, normally at least four of these variables are specified, for example: inlet water temperature, outlet air temperature, water flow rate, air flow rate, so that the system of equations is effectively closed.

In order to manipulate these equations, the log mean temperature and enthalpy differences are expanded as shown in Equations and . Finally, a linear approximation of the enthalpy of saturated air over the range of surface temperature is made using Equation . Note that in Equation Hw refers to the enthalpy of saturated air at the water temperature.

Equation is derived from the above equations and is used to solve for the coil conditions when all of the inlet conditions are given as input. Operating in this manner, the coil does not have a controlled outlet air temperature.

An alternative solution method is to define the coil leaving air temperature as an input with a variable water flow rate. In this case Equations and are more convenient. Equations through define terms that are used to simplify Equations , and .

Underlying Correlations, Properties, and Assumptions[LINK]

Overall heat transfer coefficients are calculated from the specified coil geometry and by using empirical correlations from fluid mechanics and heat transfer. For the water side, Equation gives the film heat transfer coefficient in SI units:

This is valid for Reynolds numbers greater than 3100 based on water flow velocity and pipe inside diameter and is given in Elmahdy and Mitalas (1977) as recommended in the standard issued by the Air-Conditioning and Refrigeration Institute (1972) for air-cooling coils. The definition of overall inside thermal resistance follows directly as shown in Equation.

Equation gives the film coefficient for the air side. Another form of the same equation is Equation , which is familiar from the data presented in Kays and London (1984). For coil sections that have a wet surface due to condensation, the air side film coefficient is modified according to Equation . The correction term, a function of air Reynolds number, is valid for Reynolds numbers between 400 and 1500. The coefficients in Equation and are calculated by Equations and that are functions of the coil geometry. Elmahdy (1977) explains the modifier for the wet surface and coefficients for the film coefficient. Equations through show definitions and values of common parameters and properties.

The film coefficients above act on the extended surface of the air side, that is the area of the fins and the tubes. Therefore, the fin efficiency must also be considered in calculating the overall thermal resistance on the outside. Gardner (1945) gives the derivation of Equation , used as a curve fit to find the fin efficiency as a function of film coefficient. This equation is based on circular fins of constant thickness. To model a coil with flat fins, an effective diameter – that of circular fins with the same fin area – is used. Equations through define variables used in Equation . The overall efficiency of the surface is shown by Equation . Note that the efficiency is found by the same equations for the wet surface using the wet surface film coefficient.

The definition of overall outside thermal resistance is given in Equation as a function of fin efficiency and film coefficient. For a wet coil surface the resistance must be defined differently because the heat transfer equations are based on enthalpy rather than temperature differences, as shown in Equation .

Equation gives the last two overall components of thermal resistance. They represent the metal tube wall and internal fouling. The fouling factor, due to deposits of dirt and corrosion of the tube inside surfaces, is assumed to be 5x10-5 m2·K/W. All components of thermal resistance are added in series to produce the overall heat transfer coefficients shown in Equations and .

Solution Method of Model[LINK]

The complicated equations derived above were implemented in a successive substitution solution procedure to calculate the coil performance based on the input parameters. The MODSIM implementation of a cooling coil, the TYPE12 subroutine, was the motivation for this approach; the method used there has been retained with modifications for the uncontrolled coil model. Clark (1985) contains notes about the MODSIM routine.

In the general case, the cooling coil is only partially wet. For an uncontrolled coil, Equation is used to find the water temperature at the boundary. Several simple equations in the loop adjust the boundary point until the dry surface temperature at the boundary is equal to the dewpoint of the inlet air. For the controlled coil, Equations and give two calculations of the boundary temperature, and the water flow rate and boundary position are adjusted until the two equations agree.

Special cases occur when the coil is all wet or all dry. The coil is solved as if it were all wet before the general case is attempted. If the wet surface temperatures at the coil inlet and outlet are both below the dewpoint, no further solution is required. However, to ensure a continuous solution as flow variables are changed, when the surface is all dry or when it is wet with only the dry surface equations yielding a surface temperature below the dewpoint at the water outlet, the general solution is used to calculate the unknowns. In the solution of the controlled coil the outlet air enthalpy, given some resulting dehumidification, must correspond to the enthalpy at the specified outlet air temperature.

Application of Cooling Coil Model to Heating Coils[LINK]

The implementation of detailed heating coil models in IBLAST was another important aspect of the system/plant integration. The same kind of loops exist to provide hot water to the heating coils from the boilers as exist to supply the cooling coils with chilled water from the chillers. Some simplifications can be made, however, since the enthalpy change of the air flowing over a heating coil is entirely sensible. There is no condensation in a heating coil. In order to allow heating and cooling coils to be specified using the same geometric parameters, a heating coil simulation was developed from the cooling coil model described above by eliminating the wet surface analysis.

In addition, it was concluded that, since much simpler and less computationally expensive heating coil simulations are possible, an option was provided in IBLAST for a heating coil design using only the UA value of the coil, the product of heat transfer coefficient and coil area. This model was largely based on the TYPE10 subroutine implemented in MODSIM. The equations used to model the performance of the TYPE10 heating coil are as follows:

where the coil effectiveness is given by:

The parameter NTU is the number of transfer units and is defined as a function of the UA value of the coil as follows:

Hot-Water-Based Air Heating Coil[LINK]

The input object Coil:Heating:Water provides a model that uses an NTU–effectiveness model of a static heat exchanger. The model is an inlet – outlet model: given the inlet conditions and flow rates and the UA, the effectiveness is calculated using the formula for the effectiveness of a cross-flow heat exchanger with both fluid streams unmixed. The effectiveness then allows the calculation of the outlet conditions from the inlet conditions.

The inputs to the model are: (1) the current inlet temperatures and flow rates of the air and water fluid streams and (2) the UA of the coil. Note that the UA is fixed in this model and is not a function of the flow rates.

There are 2 alternative user inputs for the component: the user may input the design water volumetric flow rate and the UA directly; or the user may choose to input the more familiar design heating capacity plus design inlet & outlet temperatures and let the program calculate the design UA. These alternative user inputs are fully described in the EnergyPlus Input Output Reference document.

Model Description[LINK]

The air and water capacitance flows are defined as:

The minimum and maximum capacity flows are then:

The capacitance flow ratio is defined as:

The number of transfer units (NTU) is:

The effectiveness is:

Where  .

.

The outlet conditions are then:

The output of the coil in watts is:

The UA value is recalculated for each timestep. A nominal UA, UA0, at the rating point is calculated by the program using the input for rated conditions and a search routine called regula falsi.

User input for the ratio of convective heat transfers at the nominal or rated operating point, “r,” is used in the model. This ratio is defined as

where,

is the fin efficiency, (dimensionless)

is the fin efficiency, (dimensionless)

h is the surface convection heat transfer coefficient

A is the surface area

The value calculated for UA0is used with the input for r to characterize the convective heat transfer on the water sides at the nominal rating operation point using

and on the air side at the nominal rating point using

Then the following equations are used to calculate a new UA as a function of the flow rates and inlet temperatures at each timestep.

The above formulas are from the following reference, along with further references. The equation for xw was modified from that published in Wetter (1999) to correct a small error.

Wetter, M. 1999. Simulation Model: Finned Water-to-Air Coil Without Condensation. LBNL-42355. This document can be downloaded from http://simulationresearch.lbl.gov.

Single-Speed Electric DX Air Cooling Coil[LINK]

This model (object names Coil:Cooling:DX:SingleSpeed and Coil:Cooling:DX:TwoStageWithHumidityControlMode, with CoilPerformance:DX:Cooling) simulates the performance of an air-cooled or evaporative-cooled direct expansion (DX) air conditioner. The model uses performance information at rated conditions along with curve fits for variations in total capacity, energy input ratio and part-load fraction to determine the performance of the unit at part-load conditions (Henderson et al. 1992, ASHRAE 1993). Sensible/latent capacity splits are determined by the rated sensible heat ratio (SHR) and the apparatus dewpoint (ADP)/bypass factor (BF) approach. This approach is analogous to the NTU-effectiveness calculations used for sensible-only heat exchanger calculations, extended to a cooling and dehumidifying coil.

This model simulates the thermal performance of the DX cooling coil and the power consumption of the outdoor condensing unit (compressor, fan, crankcase heater and evap condenser water pump). The total amount of heat rejected by the condenser is also calculated and stored for use by other waste heat recovery models (e.g., Coil:Heating:Desuperheater). The performance of the indoor supply air fan varies widely from system to system depending on control strategy (e.g., constant fan vs. AUTO fan, constant air volume vs. variable air volume, etc.), fan type, fan motor efficiency and pressure losses through the air distribution system. Therefore, this DX system model does not account for the thermal effects or electric power consumption of the indoor supply air fan. EnergyPlus contains separate models for simulating the performance of various indoor fan configurations, and these models can be easily linked with the DX system model described here to simulate the entire DX air conditioner being considered (e.g., see AirLoopHVAC:Unitary:Furnace:HeatCool, AirLoopHVAC:UnitaryHeatCool, ZoneHVAC:WindowAirConditioner or AirLoopHVAC:UnitaryHeatPump:AirToAir).

Model Description[LINK]

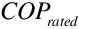

The user must input the total cooling capacity, sensible heat ratio (SHR), coefficient of performance (COP) and the volumetric air flow rate across the cooling coil at rated conditions. The capacity, SHR and COP inputs should be “gross” values, excluding any thermal or energy impacts due to the indoor supply air fan. The rated conditions are considered to be air entering the cooling coil at 26.7°C drybulb/19.4°C wetbulb and air entering the outdoor condenser coil at 35°C drybulb/23.9°C wetbulb. The rated volumetric air flow should be between 0.00004027 m3/s and 0.00006041 m3/s per watt of rated total cooling capacity (300 – 450 cfm/ton). The rated volumetric air flow to total cooling capacity ratio for 100% dedicated outdoor air (DOAS) application DX cooling coils should be between 0.00001677 (m3/s)/W (125 cfm/ton) and 0.00003355 (m3/s)/W (250 cfm/ton).

The user must also input five performance curves that describe the change in total cooling capacity and efficiency at part-load conditions:

- Total cooling capacity modifier curve (function of temperature)

- Total cooling capacity modifier curve (function of flow fraction)

- Energy input ratio (EIR) modifier curve (function of temperature)

- Energy input ratio (EIR) modifier curve (function of flow fraction)

- Part load fraction correlation (function of part load ratio)

- The total cooling capacity modifier curve (function of temperature) is a biquadratic curve with two independent variables: wet-bulb temperature of the air entering the cooling coil, and dry-bulb temperature of the air entering the air-cooled condenser coil (wet-bulb temperature if modeling an evaporative-cooled condenser). The output of this curve is multiplied by the rated total cooling capacity to give the total cooling capacity at the specific entering air temperatures at which the DX coil unit is operating (i.e., at temperatures different from the rating point temperatures).

Note: The data used to develop the total cooling capacity modifier curve (function of temperature) should represent performance when the cooling coil is ‘wet’ (i.e., coil providing sensible cooling and at least some dehumidification). Performance data when the cooling coil is ‘dry’ (i.e., not providing any dehumidification) should not be included when developing this modifier curve. This model automatically detects and adjusts for ‘dry coil’ conditions (see section “Dry Coil Conditions” below).

where

= wet-bulb temperature of the air entering the cooling coil, °C

= wet-bulb temperature of the air entering the cooling coil, °C

= dry-bulb temperature of the air entering an air-cooled condenser or wet-bulb

= dry-bulb temperature of the air entering an air-cooled condenser or wet-bulb

temperature of the air entering an evaporative-cooled condenser, °C

- The total cooling capacity modifier curve (function of flow fraction) is a quadratic (or cubic) curve with the independent variable being the ratio of the actual air flow rate across the cooling coil to the rated air flow rate (i.e., fraction of full load flow). The output of this curve is multiplied by the rated total cooling capacity and the total cooling capacity modifier curve (function of temperature) to give the total cooling capacity at the specific temperature and air flow conditions at which the DX unit is operating.

or

where

Note: The actual volumetric air flow rate through the cooling coil for any simulation time step where the DX unit is operating must be between 0.00002684 m3/s and .00006713 m3/s per watt of rated total cooling capacity (200 - 500 cfm/ton). The simulation will issue a warning message if this air flow range is exceeded.

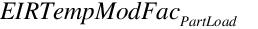

- The energy input ratio (EIR) modifier curve (function of temperature) is a biquadratic curve with two independent variables: wet-bulb temperature of the air entering the cooling coil, and dry-bulb temperature of the air entering the air-cooled condenser coil (wet-bulb temperature if modeling an evaporative-cooled condenser). The output of this curve is multiplied by the rated EIR (inverse of the rated COP) to give the EIR at the specific entering air temperatures at which the DX coil unit is operating (i.e., at temperatures different from the rating point temperatures).

Note: The data used to develop the energy input ratio (EIR) modifier curve (function of temperature) should represent performance when the cooling coil is ‘wet’ (i.e., coil providing sensible cooling and at least some dehumidification). Performance data when the cooling coil is ‘dry’ (i.e., not providing any dehumidification) should not be included when developing this modifier curve. This model automatically detects and adjusts for ‘dry coil’ conditions (see section “Dry Coil Conditions” below).

where

= wet-bulb temperature of the air entering the cooling coil, °C

= wet-bulb temperature of the air entering the cooling coil, °C

= dry-bulb temperature of the air entering an air-cooled condenser or wet-bulb

= dry-bulb temperature of the air entering an air-cooled condenser or wet-bulb

temperature of the air entering an evaporative-cooled condenser, °C

- The energy input ratio (EIR) modifier curve (function of flow fraction) is a quadratic (or cubic) curve with the independent variable being the ratio of the actual air flow rate across the cooling coil to the rated air flow rate (i.e., fraction of full load flow). The output of this curve is multiplied by the rated EIR (inverse of the rated COP) and the EIR modifier curve (function of temperature) to give the EIR at the specific temperature and air flow conditions at which the DX unit is operating.

or

where

- The part load fraction correlation (function of part load ratio) is a quadratic or a cubic curve with the independent variable being part load ratio (sensible cooling load / steady-state sensible cooling capacity). The output of this curve is used in combination with the rated EIR and EIR modifier curves to give the “effective” EIR for a given simulation time step. The part load fraction (PLF) correlation accounts for efficiency losses due to compressor cycling.

or

where

The part-load fraction correlation should be normalized to a value of 1.0 when the part load ratio equals 1.0 (i.e., no efficiency losses when the compressor(s) run continuously for the simulation time step). For PLR values between 0 and 1 (0 <= PLR < 1), the following rules apply:

PLF >= 0.7 and PLF >= PLR

If PLF < 0.7 a warning message is issued, the program resets the PLF value to 0.7, and the simulation proceeds. The runtime fraction of the coil is defined as PLR/PLF. If PLF < PLR, then a warning message is issued and the runtime fraction of the coil is limited to 1.0.

A typical part load fraction correlation for a conventional, single-speed DX cooling coil (e.g., residential or small commercial unit) would be:

PLF = 0.85 + 0.15(PLR)

All five part-load curves are accessed through EnergyPlus’ built-in performance curve equation manager (curve: quadratic, curve:cubic and curve:biquadratic). It is not imperative that the user utilize all coefficients shown in equations (449) through (453) if their performance equation has fewer terms (e.g., if the user’s PartLoadFrac performance curve is linear instead of quadratic, simply enter the values for a and b, and set coefficient c equal to zero).

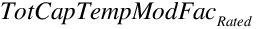

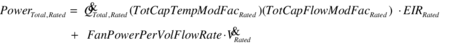

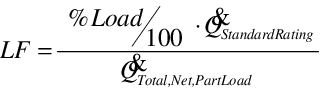

For any simulation time step, the total (gross) cooling capacity of the DX unit is calculated as follows:

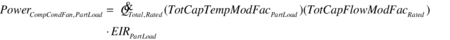

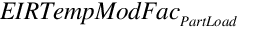

In a similar fashion, the electrical power consumed by the DX unit (compressors plus outdoor condenser fans) for any simulation time step is calculated using the following equation:

where

= Total cooling capacity, W – ref. equation (455)

= Total cooling capacity, W – ref. equation (455)

= Coefficient of performance at rated conditions (user input)

= Coefficient of performance at rated conditions (user input)

The total amount of heat rejected by the condenser is then calculated and stored for use by other waste heat recovery models (e.g., Coil:Heating:Desuperheater).

where

= total amount of heat rejected by the condenser (W)

= total amount of heat rejected by the condenser (W)

The crankcase heater is assumed to operate when the cooling coil’s compressor is OFF and the outdoor dry-bulb temperature is below the maximum outdoor temperature for crankcase heater operation. The average crankcase heater power for the simulation time step is calculated as follows:

where

= DX cooling coil crankcase heater power, W

= DX cooling coil crankcase heater power, W

= crankcase heater capacity, W

= crankcase heater capacity, W

If this cooling coil is used as part of an air-to-air heat pump (Ref. AirLoopHVAC:UnitaryHeatPump:AirToAir), the crankcase heater defined for this DX cooling coil is disregarded and the associated output variable is omitted. Instead, the crankcase heater defined for the DX heating coil (Coil:Heating:DX:SingleSpeed) is enabled during the time that the compressor is not running for either heating or cooling. In this instance, RTF in the above equations would be the runtime fraction of the heat pump’s heating coil or cooling coil, whichever is greater.

In addition to calculating the total cooling capacity provided by the DX air conditioner, it is important to properly determine the break down of total cooling capacity into its sensible (temperature) and latent (dehumidification) components. The model computes the sensible/ latent split using the rated SHR and the ADP/BF approach (Carrier et al. 1959). When the DX coil model is initially called during an EnergyPlus simulation, the rated total capacity and rated SHR are used to calculate the coil bypass factor (BF) at rated conditions. The rated total capacity and rated SHR are first used to determine the ratio of change in air humidity ratio to air dry-bulb temperature:

where

ωin~~= humidity ratio of the air entering the cooling coil at rated conditions, kg/kg

ωout~~= humidity ratio of the air leaving the cooling coil at rated conditions, kg/kg

Tdb,in~~= dry-bulb temperature of the air entering the cooling coil at rated conditions, °C

Tdb,out~~= dry-bulb temperature of the air leaving the cooling coil at rated conditions, °C

Along with the rated entering air conditions, the algorithm then searches along the saturation curve of the psychrometric chart until the slope of the line between the point on the saturation curve and the inlet air conditions matches SlopeRated. Once this point, the apparatus dewpoint, is found on the saturation curve the coil bypass factor at rated conditions is calculated as follows:

where

hout,rated ~~= enthalpy of the air leaving the cooling coil at rated conditions, J/kg

hin,rated ~~= enthalpy of the air entering the cooling coil at rated conditions, J/kg

hADP ~~= enthalpy of saturated air at the coil apparatus dewpoint, J/kg

The coil bypass factor is analogous to the “ineffectiveness” (1-ε) of a heat exchanger, and can be described in terms of the number of transfer of unit (NTU).

For a given coil geometry, the bypass factor is only a function of air mass flow rate. The model calculates the parameter Ao in equation (460) based on BFrated and the rated air mass flow rate. With Ao known, the coil BF can be determined for non-rated air flow rates.

For each simulation time step when the DX air conditioner operates to meet a cooling load, the total cooling capacity at the actual operating conditions is calculated using equation (455) and the coil bypass factor is calculated based on equation (460). The coil bypass factor is used to calculate the operating sensible heat ratio (SHR) of the cooling coil using equations (461) and (462).

where

= enthalpy of the air entering the cooling coil, J/kg

= enthalpy of the air entering the cooling coil, J/kg

= enthalpy of air at the apparatus dewpoint condition, J/kg

= enthalpy of air at the apparatus dewpoint condition, J/kg

= enthalpy of air at the entering coil dry-bulb temperature and humidity ratio at ADP, J/kg

= enthalpy of air at the entering coil dry-bulb temperature and humidity ratio at ADP, J/kg

= air mass flow rate, kg/s

= air mass flow rate, kg/s

With the SHR for the coil at the current operating conditions, the properties of the air leaving the cooling coil are calculated using the following equations:

where

= enthalpy of the air leaving the cooling coil, J/kg

= enthalpy of the air leaving the cooling coil, J/kg

= enthalpy of air at the entering coil dry-bulb temperature and leaving air humidity ratio, J/kg

= enthalpy of air at the entering coil dry-bulb temperature and leaving air humidity ratio, J/kg

= leaving air humidity ratio, kg/kg

= leaving air humidity ratio, kg/kg

= leaving air dry-bulb temperature, °C

= leaving air dry-bulb temperature, °C

PsyWFnTdbH = EnergyPlus psychrometric function, returns humidity ratio given dry-bulb temperature and enthalpy

PsyTdbFnHW = EnergyPlus psychrometric function, returns dry-bulb temperature given enthalpy and humidity ratio

Dry Coil Conditions[LINK]

If the model determines that the cooling coil is dry (ωin < ωADP), then equations (455) and (456) are invalid since they are functions of entering wet-bulb temperature. Under dry-coil conditions, coil performance is a function of dry-bulb temperature rather than wet-bulb temperature. In this case, the model recalculates the performance of the DX cooling unit using the calculation procedure described above but with ω~in =ωdry,~where ωdryis the inlet air humidity ratio at the coil dry-out point (SHR = 1.0).

SHR Calculation Using User Specified SHR Modifier Curves[LINK]

This alternative SHR calculation method is based on user specified SHR modifying curves for temperature and flow fractions. The modifying curves correct the rated SHR value for a given DX cooling coil entering air temperatures and air mass flow fraction. These SHR modifying curves are optional additional curve inputs to the DX cooling coil objects. These two curves are a biquadratic SHR modifier curve for temperature (SHRFT), and a quadratic SHR correction curve for flow fraction (SHRFFF).

Biquadratic SHR modifier normalized curve for DX cooling coil entering air (outdoor) wet-bulb and dry-bulb temperatures. The coil entering conditions can be outdoor air or pretreated outdoor air.

Quadratic SHR modifier curve for flow fraction.

The SHR is given by:

The cooing coil outlet air enthalpy is given by:

The cooling coil outlet air enthalpy at the coil enlet air temperature and coil outlet humidity ratio is given by:

The DX cooling coil outlet air humidity ratio is calculated from the psychometric function as follows:

The DX cooling coils leaving humidity ratio cannot exceed the DX coil entering air humidity ratio. And for dry air condition entering the cooling coil, the above equation may yield unrealistic (in some cases negative values) coil outlet humidity ratio. In this case the coil outlet air humidity is set a small value as follows:

The DX cooling coil outlet air dry-bulb temperature is determined as follows:

where

= sensible heat ratio modifier normalized biquadratic curve as a function of coil entering air wet-bulb and dry-bulb temperatures, (-). The DX cooling coil entering air temperature can be the outdoor air condition or pretreated outdoor air when the DX cooling coil is placed after an exhaust heat recovery heat exchangers.

= sensible heat ratio modifier normalized biquadratic curve as a function of coil entering air wet-bulb and dry-bulb temperatures, (-). The DX cooling coil entering air temperature can be the outdoor air condition or pretreated outdoor air when the DX cooling coil is placed after an exhaust heat recovery heat exchangers.

= sensible heat ratio modifier normalized quadratic curve as a function of air mass flow fraction. Flow fraction is the ratio of actual to rated mass flow rate of air through the DX cooling coil, (-).

= sensible heat ratio modifier normalized quadratic curve as a function of air mass flow fraction. Flow fraction is the ratio of actual to rated mass flow rate of air through the DX cooling coil, (-).

= sensible heat ratio at rated condition, (-).

= sensible heat ratio at rated condition, (-).

Condenser Options: AirCooled vs. EvaporativelyCooled[LINK]

As described previously, this model can simulate the performance of air-cooled or evaporative-cooled DX air conditioners. The following paragraphs describe three modeling options.

If the user wants to model an air-cooled condenser, they should simply specify AirCooled in the field Condenser Type. In this case, the Total Cooling Capacity Modifier Curve (function of temperature) and the Energy Input Ratio Modifier Curve (function of temperature) (equations (449) and (451) above) will utilize the outdoor dry-bulb temperature.

If the user wishes to model an evaporatively-cooled condenser AND they have performance curves that are a function of the wet-bulb temperature of air entering the condenser coil, then the user should specify Condenser Type = EvaporativlyCooled and the evaporative condenser effectiveness value should be entered as 1.0. In this case, the Total Cooling Capacity Modifier Curve (function of temperature) and the Energy Input Ratio Modifier Curve (function of temperature) (equations (449) and (451) above) will utilize the outdoor wet-bulb temperature.

If the user wishes to model an air-cooled condenser that has evaporative media placed in front of it to cool the air entering the condenser coil, then the user should specify Condenser Type = EvaporativelyCooled. The user must also enter the appropriate evaporative effectiveness for the media. In this case, the Total Cooling Capacity Modifier Curve (function of temperature) and the Energy Input Ratio Modifier Curve (function of temperature) will utilize the condenser inlet air temperature as calculated below:

where

Tc,i~~= the temperature of the air entering the condenser coil, °C

Twb,o~~= the wet-bulb temperature of the outdoor air, °C

Tdb,o~~= the dry-bulb temperature of the outdoor air, °C

In this case, the Total Cooling Capacity Modifier Curve (function of temperature) and the Energy Input Ratio Modifier Curve (function of temperature) input fields for this object should reference performance curves that are a function of outdoor dry-bulb temperature. Be aware that the evaporative media will significantly reduce the dry-bulb temperature of the air entering the condenser coil, so the Total Cooling Capacity and EIR Modifier Curves must be valid for the expected range of dry-bulb temperatures that will be entering the condenser coil.

If an evaporatively-cooled condenser is modeled, the power requirements for the water pump are calculated as follows:

where

= DX cooling coil evap condenser pump electric power, W

= DX cooling coil evap condenser pump electric power, W

= evaporative condenser pump rated power consumption, W

= evaporative condenser pump rated power consumption, W

Water consumption for the evaporative-cooled condenser is calculated using the difference in air humidity level across the evaporative media and the condenser air mass flow rate:

where

= DX cooling coil evap condenser water consumption, m3

= DX cooling coil evap condenser water consumption, m3

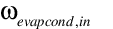

= evaporative condenser air mass flow rate, kg/s

= evaporative condenser air mass flow rate, kg/s

= humidity ratio of outdoor air entering the evap condenser, kg/kg

= humidity ratio of outdoor air entering the evap condenser, kg/kg

= humidity ratio of air leaving the evap condenser, kg/kg

= humidity ratio of air leaving the evap condenser, kg/kg

= density of water at the outdoor dry-bulb temperature, kg/m3

= density of water at the outdoor dry-bulb temperature, kg/m3

TimeStepSys = HVAC system simulation time step, hr

Condenser Inlet Air Temperature[LINK]

The air temperature entering the outdoor condenser is based on the weather data used during a simulation. This temperature is either taken directly from the weather data, or can be adjusted based on the height of the outdoor condenser. The input for Condenser Air Inlet Node Name can be used to control this optional feature. If this input is left blank, the air temperature entering the condenser is based soley on the weather data. If this input is not blank, then the node name specified must also be listed in an OutdoorAir:Node or OutdoorAir:NodeList object. When the node name is listed in an OutdoorAir:NodeList object, the air temperature entering the condenser is based soley on the weather data. When the node name is listed in an OutdoorAir:Node object, the height of the node determines the air temperature entering the outdoor condenser (see description of Local Outdoor Air Temperature Calculation in the Atmospheric Variation section of this document for further details).

Supply Air Fan Control: Cycling vs. Continuous[LINK]

The DX cooling coil model simulates two specific supply air fan operation modes: cycling fan, cycling compressor or continuous fan, cycling compressor. The first operation mode is frequently referred to as “AUTO fan”, where the compressor(s) and supply air fan operate in unison to meet the zone cooling load, and cycle off together when the cooling load has been met. The second operation mode is often referred to as “fan ON”, where the compressor(s) cycle on and off to meet the zone cooling load but the supply air fan operates continuously regardless of compressor operation.

Since this DX heating coil can only be used in conjunction with a DX cooling coil (i.e. heat pumps), and these coils are used in AC equipment that specifies a fan operation mode schedule (e.g AirLoopHVAC:UnitaryHeatPump:AirToAir), the fan operation mode schedule value determines the fan operation mode for each time step throughout the simulation. A fan operation mode schedule value of 0 specifies AUTO fan mode operation while values other than 0 (a 1 is usually used) specify fan ON operation. The use of a schedule allows the fan operation mode to change based on time-of-day or with changes in season.

The EnergyPlus methodology for determining the impact that HVAC equipment has on an air stream is to calculate the mass flow rate and air properties (e.g., enthalpy, dry-bulb temperature, humidity ratio) exiting the equipment. These exiting conditions are passed along as inlet conditions to the next component model in the air stream. Eventually the flow rate and properties of the air being supplied to the conditioned zone are used in the zone energy balance to determine the resulting zone air temperature and humidity ratio. With this methodology, the determination of the air mass flow rate and air properties for the two different supply air fan operation modes is slightly different.

Cycling Fan Mode:

For the case of cycling fan/cycling compressor when humidity control is not specified, the conditions of the air leaving the cooling coil are the steady-state values calculated using equations (463), (465) and (466) above. However the air mass flow rate passed along to the next component (and eventually to the conditioned zone) is the average air mass flow rate for the system simulation time step (determined by the cooling system; see ZoneHVAC:WindowAirConditioner, AirLoopHVAC:Unitary:Furnace:HeatCool, AirLoopHVAC:UnitaryHeatCool, or AirLoopHVAC:UnitaryHeatPump:AirToAir).

For the case of cycling fan/cyling compressor when humidity control is specified, the conditions of the air leaving the cooling coil are calculated as the average conditions during the fan operating period. When the compressor operates in tandem with the fan (i.e., compressor part-load ratio [PLR] is equal to the fan PLR), the outlet conditions are identical to the calculations described above. When the compressor operates for a shorter duration than the fan (i.e., the compressor PLR is less than the heating/fan PLR), the air properties leaving the cooling coil are calculated as the average conditions during the fan operating period. In this case the calculation of exiting air conditions is analogous to the calculations for continuous fan mode described below except that PLR in the equations represents the ratio of the compressor to the fan operating period. For cycling fan systems, the fan will only operate longer than the compressor, and therefore latent degradation may be modeled (user input), when humidity control is specified, a moisture load exists (i.e., the zone air humidistat senses a moisture load), and a heating load exists where the heating PLR is greater than the cooling PLR.

Continuous Fan Mode:

For the case of continuous fan/cycling compressor, the air mass flow rate is constant. However, the air properties leaving the cooling coil are calculated as the average conditions during the system simulation time step. The model assumes that the exiting air conditions are the steady-state values calculated using equations (463), (465) and (466) above when the compressor(s) operate. For the remainder of the system simulation time step, it is assumed that the air exiting the DX coil has the same properties as the air entering the coil. For this supply air fan operating strategy, the leaving air properties are calculated as follows:

Latent Capacity Degradation[LINK]

The latent (dehumidification) capacity of a direct-expansion (DX) cooling coil is strongly affected by part-load, or cyclic, operation. This is especially true in applications where the supply air fan operates continuously while the cooling coil cycles on and off to meet the cooling load. During constant fan operation, moisture condenses on the cooling coil when the compressor operates, but part or all of the moisture that is held by the coil evaporates back into the airstream when the cooling coil is deactivated (Figure 167). The net effect is that the amount of moisture removed from the air is degraded at part-load conditions as compared to steady-state conditions when the compressor operates continuously (Figure 168).

EnergyPlus is able to model latent capacity degradation based on algorithms developed by Henderson and Rengarajan (1996). The model is applicable to single-stage cooling units, like residential and small commercial air conditioners or heat pumps with less than 19 kW of nominal cooling capacity. The model inputs are described in the EnergyPlus Input/Output Reference for the object Coil:Cooling:DX:SingleSpeed. The model is enabled only if the four numerical inputs are defined (values greater than zero, see IO Reference).

The following discussion applies to both cycling fan and continuous fan operation when the fan operates for a longer period of time than the compressor and air continues to flow over the moisture laden cooling coil after compressor operation has terminated.

Figure 169 graphically depicts the latent degradation concepts and defines several key model parameters. After the cooling coil starts to operate, the coil temperature is eventually reduced below the dewpoint temperature of the entering air. Moisture from the air then builds on the surface of the coil until time to has elapsed and the total moisture mass on the coil is Mo. After this time (to), moisture begins to fall from the coil and all of the latent capacity provided by the coil is “useful” since this condensate is collected and removed from the unit. When the coil cycles off and the supply air fan continues to operate, the initial moisture mass buildup on the coil (Mo) evaporates back into the supply air stream. If the cooling coil cycles back on before all of the moisture has evaporated, then the time until the first condensate removal (to) is shorter for this cooling cycle since the coil is already partially wetted.

Figure 169 also shows several parameters that are used in the latent degradation model. The ratio of the coil’s moisture holding capacity (Mo) and the steady-state latent capacity ( ) is defined as twet : the nominal time for moisture to fall from the coil (ignoring transient effects at startup and starting with a dry coil). The ratio of the initial moisture evaporation rate (

) is defined as twet : the nominal time for moisture to fall from the coil (ignoring transient effects at startup and starting with a dry coil). The ratio of the initial moisture evaporation rate ( ) and the steady-state latent capacity (

) and the steady-state latent capacity ( ) is defined as

) is defined as  . Both twet and

. Both twet and  at the rated air volume flow rate and temperature conditions are required model inputs. Two other model inputs are the Maximum ON/OFF Cycling Rate (cycles per hour, Nmax) and the time constant (

at the rated air volume flow rate and temperature conditions are required model inputs. Two other model inputs are the Maximum ON/OFF Cycling Rate (cycles per hour, Nmax) and the time constant ( , in seconds) for the cooling coil’s latent capacity to reach steady state after startup. The development of the latent degradation model is fully described by Henderson and Rengarajan (1996). The model implemented in EnergyPlus is for their “linear decay” evaporation model.

, in seconds) for the cooling coil’s latent capacity to reach steady state after startup. The development of the latent degradation model is fully described by Henderson and Rengarajan (1996). The model implemented in EnergyPlus is for their “linear decay” evaporation model.

During the simulation, all of the steady-state calculations described previously in equations (449) through (462) are completed. The latent degradation model then modifies the steady-state sensible heat ratio for the coil as shown below. The value of twet at the current air volume flow rate and entering air conditions is first calculated based on the rated value of twet entered by the user:

where

twet = nominal time for condensate removal to begin at the current airflow and entering air conditions, starting with a dry coil (sec)

twet,rated = nominal time for condensate removal to begin at the coil’s rated airflow and entering air conditions, starting with a dry coil (sec)

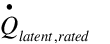

= cooling coil latent capacity at the rated airflow and temperature conditions, W

= cooling coil latent capacity at the rated airflow and temperature conditions, W

= cooling coil latent capacity at the current airflow and temperature conditions, W

= cooling coil latent capacity at the current airflow and temperature conditions, W

twet,max = maximum allowed value for twet (9999.0 sec)

Likewise, the value of  at the current air volume flow rate and entering air conditions is calculated based on the rated value of

at the current air volume flow rate and entering air conditions is calculated based on the rated value of  entered by the user:

entered by the user:

where:

= ratio of the initial moisture evaporation rate from the cooling coil (when the compressor first turns off, in Watts) and the coil’s steady-state latent capacity (Watts) at the current air volume flow rate and entering air conditions

= ratio of the initial moisture evaporation rate from the cooling coil (when the compressor first turns off, in Watts) and the coil’s steady-state latent capacity (Watts) at the current air volume flow rate and entering air conditions

=

=  at rated air flow and entering air conditions

at rated air flow and entering air conditions

Tdb,i = dry-bulb temperature of the air entering the cooling coil, °C

Twb,i = wet-bulb temperature of the air entering the cooling coil, °C

Tdb,rated = dry-bulb temperature of air entering the cooling coil at rated conditions (26.7°C)

Twb,rated= wet-bulb temperature of air entering the cooing coil at rated conditions (19.4°C)

The cooling coil on and off times are then calculated based on the maximum number of cycles per hour and the calculated run-time fraction for the coil.

where

ton= duration of cooling coil on-cycle (sec)

Nmax= maximum on/off cycles per hour (cph)

X= cooling coil runtime fraction (-)

toff= duration of cooling coil off-cycle (sec)

For cycling fan systems, the duration of the heating coil on and off cycles are also calculated. When the heating coil operates for a longer duration of time than the cooling coil, latent degradation can also occur. For this case, the off-cycle time (i.e., the amount of time the fan operates longer than the cooling coil) is recalculated and based on the difference between the heating coil on-cycle time and the cooling coil on-cycle time. Ton and Toff for the heating coil are calculated in the same manner as shown above except that the heating run-time fraction is used for the calculations. This model assumes that the cycling rate of the cooling and heating coils are the same. In addition, since the heating coil cycling rate may be different than the cooling coil (based on run-time fractions), the heating coil may also turn on again before the next cooling coil on-cycle. The following equations are used when the heating coil operates for a longer time period than does the cooling coil.

where

ton,heating= duration of heating coil on-cycle (sec)

X,heating= heating coil runtime fraction (-)

toff,heating= duration of heating coil off-cycle (sec)

The equation for calculating the time to when moisture first begins to fall from the cooling coil is shown below, and is solved iteratively by EnergyPlus:

where

= time where condensate removal begins (sec)

= time where condensate removal begins (sec)

= latent capacity time constant at start-up (sec)

= latent capacity time constant at start-up (sec)

j= iteration number

The part-load latent heat ratio of the cooling coil is then calculated with  , ton and

, ton and  , which is in turn used to calculate the “effective” sensible heat ratio of the cooling including part-load latent degradation effects.

, which is in turn used to calculate the “effective” sensible heat ratio of the cooling including part-load latent degradation effects.

where

= part-load latent heat ratio

= part-load latent heat ratio

= latent heat ratio at steady-state conditions (

= latent heat ratio at steady-state conditions ( with

with  from eqn. (462))

from eqn. (462))

= part-load sensible heat ratio **(

= part-load sensible heat ratio **( ≤

≤ ≤ 1.0)

≤ 1.0)

= steady-state sensible heat ratio (from eqn. (462))

= steady-state sensible heat ratio (from eqn. (462))

With the “effective” SHR for the coil at the current operating conditions, including the impacts of latent degradation, equations (463) through (466) are then used to calculate the properties of the air leaving the cooling coil when it operates. Finally, equations (467) through (469) are used to calculate the average leaving air conditions (average when the coil is on and off) for the simulation time step.

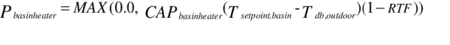

Basin Heater For Single-Speed DX Coil[LINK]

Calculations are also made to estimate the electric power input to the DX coil basin heater. A schedule may be used to disable the basin heater during regular maintenance periods or other time periods (e.g., during summer). If a schedule is not provided, the basin heater is assumed to be available the entire simulation time period. The basin heater operates when it is scheduled on, the outdoor air dry-bulb temperature is below the basin heater setpoint temperature, and the DX coil is not active. The user is required to enter a basin heater capacity (watts per degree Kelvin) and a heater setpoint temperature (oC) if they want to model basin heater electric power.

where:

= DX coil basin heater electric power (W)

= DX coil basin heater electric power (W)

= DX coil basin heater electric consumption (J)

= DX coil basin heater electric consumption (J)

= Basin heater setpoint temperature (oC)

= Basin heater setpoint temperature (oC)

= Outdoor air dry-bulb temperature (oC)

= Outdoor air dry-bulb temperature (oC)

= Basin heater capacity (W/K)

= Basin heater capacity (W/K)

= Run time fraction of DX cooling coil

= Run time fraction of DX cooling coil

The multimode DX coil uses 1 to 4 set of performance specifications which all feed into the main DX coil model as described above. The multimode DX coil may have 1 or 2 capacity stages and may have 1 enhanced dehumidification mode in addition to its “normal” or base mode performance. Any mode may specify that a portion of the total airflow is bypassed.

Bypass Operation[LINK]

When a mode has coil bypass, the non-bypassed air flow fraction is used to model the DX coil performance as described above. Then the bypassed air stream is mixed with the conditioned air stream and these conditions are place on the coil outlet node.

Multi-Stage Operation[LINK]

Multi-stage control is modeled with the DX coil. If 2-stage operation has been specified, stage 1 is assumed to operate first and continue to operate if stage 2 is required. If latent degradation is active, only one of the stages will be degraded. If stage 1 operates for less than the full time step, then latent degradation is applied. If stage 2 operates, then stage 1 is running for the full time step and latent degradation is applied only to the portion of the latent load which is attributed to stage 2 operation.

Enhanced Dehumidification Mode[LINK]

If enhanced dehumidification mode is available, this is controlled by the parent object of the DX coil, such as DXSystem:AirLoop. A dehumidification mode flag is passed to the coil model which is used to select a different set of performance specifications from a CoilPerformance:DX:Cooling input object. Then the simulation of the DX coil proceeds as described above including any bypass or multi-stage operation.

Standard Rating of Single-Speed DX Cooling Coils[LINK]

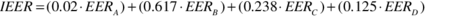

For small single-speed direct expansion (DX) cooling coils, the industry standard ratings of Standard Rating Cooling Capacity and Seasonal Energy Efficiency Ratio (SEER) are calculated according to ANSI/AHRI Standard 210/240 (AHRI 2008). These ratings apply to unitary air conditioners and air-source unitary heat pumps with air-cooled condensers with standard rating cooling capacities under 19 kW (<65,000 Btu/hr). For larger DX cooling coils, the industry standard ratings of Standard Rating Cooling Capacity, Energy Efficiency Ratio (EER), and Integrated Energy Efficiency Ratio (IEER) are calculated according to ANSI/AHRI Standard 340/360 (AHRI 2007). These ratings apply to unitary air conditioners and air-source unitary heat pumps with standard rating cooling capacities from 19 kW to below 73.2 kW (65,000 Btu/hr to <250,000 Btu/hr).

For the Coil:Cooling:DX:SingleSpeed object in EnergyPlus, these standard ratings are not direct inputs to the model. However, these standard ratings can be calculated using user-entered information for the Coil:Cooling:DX:SingleSpeed object. Since users sometimes lump the performance of several smaller DX cooling units into a single larger cooling coil object for simulation purposes, EnergyPlus outputs the Standard Rating Cooling Capacity, SEER, EER, and IEER regardless of the magnitude of the standard rating cooling capacity of the coil. It is up to the user to determine which standard ratings are applicable to the cooling coil(s) they are modeling. These standard rating values are provided in the eplusout.eio output file (Ref. OutputDetailsAndExamples.pdf) and also in the predefined tabular output reports (Output:Table:SummaryReports object, Equipment Summary). Currently, the standard ratings are only calculated and output for single-speed DX cooling coils with air-cooled condensers. If the single-speed DX coling coil is specified with an evaporatively-cooled condenser, then no standard ratings are output from EnergyPlus at this time.

Note: The standard ratings described in this section require that the DX cooling coil model be evaluated at specific operating conditions (i.e., specific wet-bulb temperatures for air entering the cooling coil and dry-bulb temperatures for air entering the air-cooled [outdoor] condenser). If the cooling coil performance curves can not be evaluated at the required test conditions, then a standard rating value calculated at the curves limit will be output and a warning message will written to eplusout.err. For example, if the curve object (Curve:Biquadratic) for Total Cooling Capacity Function of Temperature Curve has a minimum value of 21C for dry-bulb temperature entering the air-cooled condenser coil, the IEER calculation requires that EERD be calculated at 18.3C – so, this would result in IEER calculatd at user specified curve limit as an output and a warning message in the eplusout.err file.

The standard rating cooling capacity (AHRI 2007, AHRI 2008) is calculated as follows:

where,

= Standard Rating (Net) Cooling Capacity (W)

= Standard Rating (Net) Cooling Capacity (W)

= Rated Total (Gross) Cooling Capacity, user input (W)

= Rated Total (Gross) Cooling Capacity, user input (W)

= Total Cooling Capacity Function of Temperature Curve evaluated with 19.44°C wet-bulb temperature air entering the cooling coil and 35.0°C dry-bulb temperature air entering the air-cooled (outdoor) condenser (dimensionless)

= Total Cooling Capacity Function of Temperature Curve evaluated with 19.44°C wet-bulb temperature air entering the cooling coil and 35.0°C dry-bulb temperature air entering the air-cooled (outdoor) condenser (dimensionless)

= Total Cooling Capacity Function of Flow Fraction Curve evaluated at a flow fraction of 1.0 (dimensionless)

= Total Cooling Capacity Function of Flow Fraction Curve evaluated at a flow fraction of 1.0 (dimensionless)

= Rated Evaporator Fan Power Per Volume Flow Rate, user input ( W/(m3/s) )

= Rated Evaporator Fan Power Per Volume Flow Rate, user input ( W/(m3/s) )

= Rated Air Volume Flow Rate, user input (m3/s)

= Rated Air Volume Flow Rate, user input (m3/s)